Dr. Lipi Sairiwal is a veterinarian, working as Deputy Commissioner, Department of Animal Husbandry and Dairying, Ministry of Fisheries, AH&D, Government of India (GoI), New Delhi. She has an MVSc. in Veterinary Pharmacology & Toxicology from Govind Ballabh Pant University of Agriculture and Technology, Pantnagar, Uttarakhand.

In an exclusive interview with Poultry TRENDS magazine, Dr. Lipi Sairiwal shares about her journey, challenges, accomplishments, and her message to women.

Q: Please brief us about yourself

Dr. Lipi: Hailing from the hills of Uttarakhand, from a small town of Lansdowne I did my schooling from St Joseph’s Convent and City Montessori School, Lucknow. I pursued my Masters of Veterinary Science in Veterinary Pharmacology & Toxicology from Govind Ballabh Pant university of Agriculture and Technology, Pantnagar, Uttarakhand. I am presently working as Deputy Commissioner, Department of Animal Husbandry and Dairying, Ministry of Fisheries, Animal Husbandry and Dairying, Government of India, New Delhi. My previous assignment was working as veterinary officer in Uttarakhand State Animal Husbandry Department.

Q. Please share briefly about your journey into the field of animal husbandry. What inspired you to take up this profession?

Dr. Lipi: My journey started in this profession from serving in Uttarakhand State Animal Husbandry Department as Veterinary officer which made me understand the core requirements and the challenges faced by livestock owners in adverse climatic/geographical zones.

As Deputy Commissioner in the Department, I have an experience in the formulation of policies and the implementation of government schemes for the larger benefit of the livestock sector. I have actively worked for the digitalization of different credit-linked schemes of the Department and have explored the opportunities of strengthening the livestock sector by incentivizing the infrastructure in the livestock sector through different schemes of Government schemes. I have previously worked in various Livestock and Poultry Disease control programs, import and manufacture permission of Veterinary drugs and vaccines, feed additives/supplements, World organization of Animal Health (WOAH)-related issues, antimicrobial usage and resistance, One Health and zoonoses After joining the GoI, the root cause helped me in giving my best in framing of policies at central government.

As Deputy Commissioner in the Department, I have an experience in the formulation of policies and the implementation of government schemes for the larger benefit of the livestock sector. I have actively worked for the digitalization of different credit-linked schemes of the Department and have explored the opportunities of strengthening the livestock sector by incentivizing the infrastructure in the livestock sector through different schemes of Government schemes. I have previously worked in various Livestock and Poultry Disease control programs, import and manufacture permission of Veterinary drugs and vaccines, feed additives/supplements, World organization of Animal Health (WOAH)-related issues, antimicrobial usage and resistance, One Health and zoonoses After joining the GoI, the root cause helped me in giving my best in framing of policies at central government.

The recognition of the fact that animal husbandry has a huge scope, which is a sunrise sector and can contribute to the country’s GDP, made me choose this profession.

Q. Is there someone who has inspired you the most? Are there any other women you have drawn inspiration from?

Dr. Lipi: My daughter, despite her age, motivates me to be calm, firm, and assess every situation, being unbiased. Also, a friend of mine who has motivated, been a constant support, and always guided me in each step of my life has given me the inspiration to explore the possibilities in every field.

My mother, who has taught me to smile at every situation and keep working hard to strive even in adverse conditions, inspires me every second of my life.

Q. What are your key responsibilities as a Deputy Commissioner in the Animal Husbandry Department, Government of India?

Dr. Lipi: As a Deputy Commissioner in the department, I have been working for the credit-linked schemes, which have given me an insight to a completely different role from being a veterinarian. The new task, which was assigned to me few years back has introduced me to new challenges but on the same hand has made me aware of the huge potential the livestock sector has. Being closely associated in formulation of policies at this level has given me confidence to contribute, or I must say, given me some share as an Indian national in the Nation’s development.

My role is in the implementation of these schemes and serving the sector in the best possible ways. The interaction and the feedback from the different stakeholders, which include farmers, bankers, entrepreneurs, various industry associations, different ministries, and organizations, help me in better implementation and promoting ease of doing business.

Q. Could you highlight some of the major poultry projects or initiatives you have worked on?

Dr. Lipi: There is a range of various projects that I have come across during my career so far, and I am doing great. More than the established poultry houses, it thrills me to see the small poultry farmers whose enthusiasm and courage to take up this business as a means of entrepreneurship development. Giving emphasis on the development of rural poultry, I have been associated with various Poultry schemes through which 192 projects have been assisted so far and for technology intervention in the poultry sector, more than 300 projects are assisted for both, technology-intervened poultry farms and modern poultry feed plants.

Q. What has been your most fulfilling achievement in your career so far?

Dr. Lipi: Being a veterinarian, I have been able to contribute and shape the digitization of schemes in my department, which has not only created a fair and transparent mechanism but also helped in the ease of doing business. The paperless journey and the entire process have been made simple with the portal development of the schemes. With the help of seniors and colleagues, the digitization of these schemes is something I profoundly count on as one of the achievements.

Also, in this journey, I got various opportunities from CLFMA, Poultry Federation of India (PFI), Vets In Poultry (VIP) etc. to create awareness and represent Government of India initiatives for the Poultry and Poultry feed sector amongst various stakeholders of the poultry sector.

Q. As a woman in a leadership role, did you face any challenges in this male-dominated field? If so, how did you overcome them?

Dr. Lipi: Being a mother of two lovely kids who never fail to keep me motivated and happy and give me reason to strive well, the support and encouragement from seniors and colleagues at the workplace has always been there. Yet, if we talk about the challenges, there are, of course, different challenges for both men and women. However, we should complement each other and collaborate as a team.

For me, even if it is the smallest of the tasks, we have to do it with full dedication and hard work, and then no one can stop you win every battle with flying colours. This is the principle I keep in my mind before I start my work every single day.

Q. Have you seen a shift in gender inclusivity within the animal husbandry sector over the years?

Dr. Lipi: Yes, definitely! From top bureaucrats to women entrepreneurs to lady veterinarians to pashu sakhis, to prani mitra, there has been a huge shift, and I think everyone is doing more than justice to the roles assigned to each one of them. A woman has a soft touch for everything that is assigned to her because she is a daughter, a sister, a friend, a wife, and most importantly, a mother. Therefore, like all other professions, women in this sector are also seen soaring high.

Q. Are there any specific government programs or schemes aimed at empowering women in this sector?

Dr. Lipi: Women can avail themselves of the benefits as individuals, private companies, FPOs, FCOs, JLGs, MSME, Section 8 company and Cooperatives under Animal Husbandry Infrastructure Development Fund (AHIDF) and National Livestock Mission – Entrepreneurship Development Programme (NLM-EDP). These are the credit-linked schemes where, 3 % interest subvention with a 25% credit guarantee under AHIDF and 50% capital subsidy under NLM-EDP. Also various State governments are running programs for women and giving financial aids to them. Pranimitra, pashu sakhi, Maitri etc are some of the ways by which we can empower women.

Q. With technological advancements, how is the poultry sector evolving?

Dr. Lipi: India has reached at second ranking in terms of egg production in the world, and the poultry sector is being looked at as a sunrise sector. With some incentives, better infrastructure, and disease-free conditions can help India in exports. There is the provision of availing financial assistance under the schemes for environmentally controlled Poultry farms, this has given access to technology-assisted poultry projects to avail the financial assistance.

Q. What does International Women’s Day mean to you personally?

Dr. Lipi: International Women’s Day (IWD), celebrated annually on March 8, is a global day recognizing the social, economic, cultural, and political achievements of women. It also serves as a call to action for accelerating gender parity. But personally, I believe every day should be celebrated as Women’s Day, celebrating the genesis of your existence, nurturing you, and supporting you throughout your life.

With the physiological differences and various other challenges women face every day, men at family and work should, if not priority, at least acknowledge.

Q. How can industries and governments work together to create more opportunities for women in technical and leadership roles?

Dr. Lipi: The Government and industries will have to walk hand in hand to create more opportunities for more women in technical and leadership roles by implementing extensive recruitment and promotion practices in both Government and private sector. Various mentorship, sponsorship programs, and skill development activities can be planned by both sectors to hone the qualities and involvement of women in every role.

Q. What message would you like to give to women professionals striving for excellence in their fields?

Dr. Lipi: To work with full dedication, courage, hard work, and the best utilization of time should be practiced by each one of us to achieve the success. Always fix a target and then chase it with a positive approach. The fruit of hard work and someone’s smile is the satisfaction which will make you happy and contented. Never forget to thank the almighty for what has been bestowed on you.

A very Happy International Women’s Day to all of you. Good luck and keep smiling.

With India’s growing need for sustainable poultry production, this partnership will introduce innovative, science-backed solutions to optimize poultry performance. P. Karunanithi, Executive Vice President (Cluster Head), Animal Health Division at Alembic Pharmaceuticals Ltd., commented, “Poultry production efficiency starts with a healthy intestinal environment. By integrating Amlan’s innovative feed additive technologies into our portfolio, we are strengthening our commitment to delivering science-backed solutions that enhance poultry health and performance.”

With India’s growing need for sustainable poultry production, this partnership will introduce innovative, science-backed solutions to optimize poultry performance. P. Karunanithi, Executive Vice President (Cluster Head), Animal Health Division at Alembic Pharmaceuticals Ltd., commented, “Poultry production efficiency starts with a healthy intestinal environment. By integrating Amlan’s innovative feed additive technologies into our portfolio, we are strengthening our commitment to delivering science-backed solutions that enhance poultry health and performance.”

As Deputy Commissioner in the Department, I have an experience in the formulation of policies and the implementation of government schemes for the larger benefit of the livestock sector. I have actively worked for the digitalization of different credit-linked schemes of the Department and have explored the opportunities of strengthening the livestock sector by incentivizing the infrastructure in the livestock sector through different schemes of Government schemes. I have previously worked in various Livestock and Poultry Disease control programs, import and manufacture permission of Veterinary drugs and vaccines, feed additives/supplements, World organization of Animal Health (WOAH)-related issues, antimicrobial usage and resistance, One Health and zoonoses After joining the GoI, the root cause helped me in giving my best in framing of policies at central government.

As Deputy Commissioner in the Department, I have an experience in the formulation of policies and the implementation of government schemes for the larger benefit of the livestock sector. I have actively worked for the digitalization of different credit-linked schemes of the Department and have explored the opportunities of strengthening the livestock sector by incentivizing the infrastructure in the livestock sector through different schemes of Government schemes. I have previously worked in various Livestock and Poultry Disease control programs, import and manufacture permission of Veterinary drugs and vaccines, feed additives/supplements, World organization of Animal Health (WOAH)-related issues, antimicrobial usage and resistance, One Health and zoonoses After joining the GoI, the root cause helped me in giving my best in framing of policies at central government.

With over 150 curated sessions led by 300 industry experts, a major emphasis of VIV Asia 2025 will be on disease prevention and biosecurity, where speakers will present cutting-edge strategies for controlling infectious diseases, mitigating risks, and enhancing farm biosecurity to ensure resilient livestock production. The seminars will offer insights into the latest scientific developments, policy frameworks, and technological innovations designed to protect animal health and minimize the risk of disease outbreaks.

With over 150 curated sessions led by 300 industry experts, a major emphasis of VIV Asia 2025 will be on disease prevention and biosecurity, where speakers will present cutting-edge strategies for controlling infectious diseases, mitigating risks, and enhancing farm biosecurity to ensure resilient livestock production. The seminars will offer insights into the latest scientific developments, policy frameworks, and technological innovations designed to protect animal health and minimize the risk of disease outbreaks. The role of smart technologies and precision farming in advancing livestock management will also take center stage. Industry leaders will delve into the transformative impact of artificial intelligence, the Internet of Things (IoT), and automation in improving productivity, optimizing resource use, and reducing environmental impact. Attendees will gain valuable insights into how these innovations can be integrated into existing farming systems to drive efficiency and sustainability.

The role of smart technologies and precision farming in advancing livestock management will also take center stage. Industry leaders will delve into the transformative impact of artificial intelligence, the Internet of Things (IoT), and automation in improving productivity, optimizing resource use, and reducing environmental impact. Attendees will gain valuable insights into how these innovations can be integrated into existing farming systems to drive efficiency and sustainability.

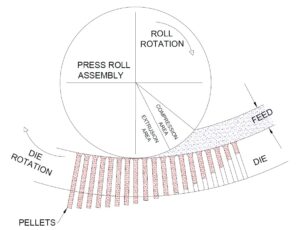

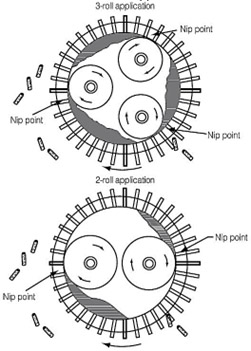

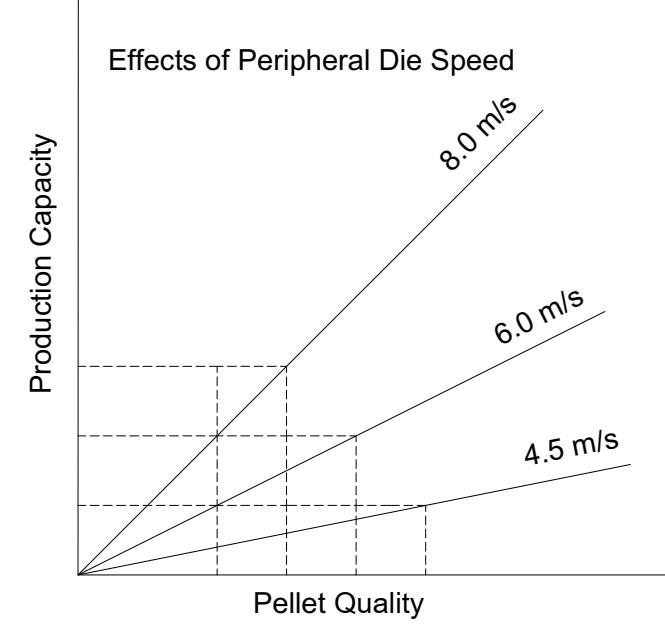

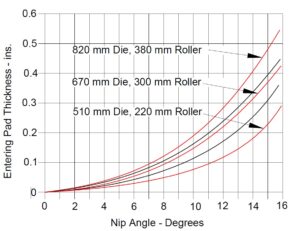

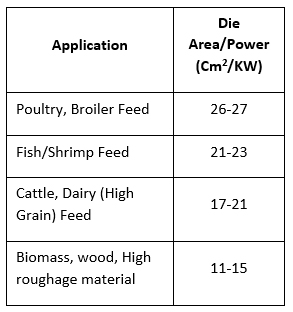

Each pellet mill is designed with a maximum power capacity in mind, and this must align with the characteristics of the materials being processed.

Each pellet mill is designed with a maximum power capacity in mind, and this must align with the characteristics of the materials being processed.