The performance of commercial broilers not only depends on a balanced nutritional diet, but also is greatly influenced by form of feed. It is found that pellet feed significantly influences the performance of the flock .

Feed form comprises two distinct elements,

- the microstructure, that describes the particle size and uniformity, and

- the macrostructure that describes pellet size, hardness, and quality.

These two factors are linked as all feeds are first reduced to particles (mash) before being pelleted. Feed is the link factor between formulator(nutritionist) and farm. So, not only nutritional value is important but also delivery of those nutrients through quality feed is equally important.

The good quality of pellet starts from good grinding

Grinding the feed ingredients into finer particles is a key factor to start quality pellet manufacturing. Particle size should be so fine that it may impact digestibility of feed. The geometric mean diameter (GMD) of the fine particles is always equal to or lower than that of mash feed, and these particles may cause a nutritional imbalance in feed chemical composition, which may negatively affect the bird performance (Muramatsu et al., 2015).Small particle size of feed causes gizzard atrophy and intestinal hypertrophy caused by bacterial fermentation

When particles are large, breakdown of feed particles at the proximal small intestine will be slower. Gizzard is the pacemaker of the GI tract. When finer feed is given, gizzard acts as a transit rather than a grinding organ. Less retention in gizzard leads to less exposures to proventriculus enzymes. It is found that a finely ground diet (560μm) compromised nutritional metabolism as particle size affects ME, nitrogen retention and DM retention. If the particle size is small ( 800 micron) feed intake is significantly reduced. On an average, a reduction of mean particle size of 100 micron will lead to a decreased feed intake of 4%.

If the feed particles are too coarse, it makes it difficult to mix a homogenous diet and feed selection. The best performance is obtained with the medium size particles 1.13 mm to 1.23 mm. It is true that a more coarsely ground maize leads to improved nutrient utilization by the birds and this remains the case when after pelleting, although the pellet press will regrind many of the larger particles. Roller mill tends to produce particles evenly distributed across a weight range, whereas a hammer mill tends to produce a greater proportion of fines and coarse particles.

Diet particle size positively influences the performance and organ and tissue growth of 21-72-day old broilers (Maiorka et al., 1998). Feed wastage tends to be higher when mash feeds are fed. In addition, the bird covers each with mucin before swallowing, which needs both protein and energy.

Nowadays most of the broiler feeds are fed in pelleted form. Injecting steam into the feed during conditioning and subsequent pressing through pellet die improves pellet durability. Pelleting is defined as the agglomeration of smaller particles into larger particles through a mechanical process combining moisture (through steam), heat, and pressure. (Abdollahi et al.,2013)

Why Pellet feed so good for commercial broiler chicken ?

It is now well-established commercial activity to manufacture and offer pellet feed in commercial broilers because of following reasons:

- Feed homogeneity is improved because feed separation is greatly reduced

- Less feed is wasted when pellets are fed

- Pelleting should slightly improve the energy value through the chemical changes brought about by heat moisture and pressure

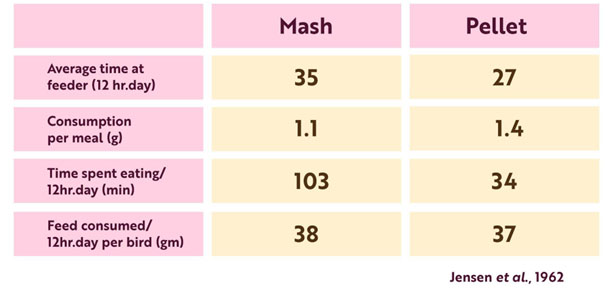

- Much of the improvement is measured energy value of pellets results from the fact that birds spend less time eating them and so their energy requirement for eating and digestion is reduced. Although pellet size may play a role in feed intake.

❖ Lilly et al. (2011) found for every 10-percentage-point increase in whole pellets there was a 0.4-point improvement in FCR and breast weight, while increasing FI

❖ Glover et al. (2016) found broilers fed a high pellet quality (90:10 pellet: fine) diet achieved a low FCR and high carcass weight, indicating production savings relative to a ground pellet diet of $0.05 to $0.03/kg of carcass weight

The Best suitable methods for measuring pellet quality

Apart from proximate values of feed ingredients, some other physical qualities like abrasiveness, pellet quality factor, color and density impact on pellet quality and durability. Pellet quality factor (PQF) has a score from 0 to 10 where o predicts poor quality and 10 indicates good pellet binding quality. Abrasiveness factor of the ingredient is just opposite to the pellet quality factor. Lower the factor value higher is the binding capacity.

Young (1962) used the technique consisting of an inclined screw, a hopper, and bucket elevator conveyor to measure pellet durability. 23 kg of pellets were continuously passed through this system for a period of 10 min. At the end of the test, the pellets were separated and the fines were removed. Calculation of the Pellet Durability Index (PDI) was percentage of the mass of surviving pellets over the total mass of pellets.

Several laboratory methods developed different technique to measure the durability of pellets like:

Tumbling box method: Commonly used method and a recognized standard in the feed industry in North America(Winowiski, 1998). The tumbling box technique uses 500 g of pellets, from which the fines have been separated. The pellets are placed in a box that revolves for the time frame of 10 min at a speed of 100 rpm. After this process, the pellets are screened on a mechanical sieve shaker. The PDI is calculated as the weight of the pellets retained on the screen divided by the total weight of pellets. (ASAE Standards, 2003)

Holmen durability tester: It is a pneumatic method of measuring the durability of the pellets. A sample size of 100 g of pellets is placed through tubes with high velocity air for 30 to 120 s, replicating the handling process. Breakage occurs when pellets strike the right-angle corners of the tester. The PDI is calculated as the weight of the pellets retained on the screen divided by the total weight of pellets. (ASAE Standards, 2003)

The Stokes hardness tester: The tester comprises a calibrated spring, a cone with a tip, and a plate supporting the opposite side of the cone. The cone tip applies pressure on the cylindrical surface of the pellet during testing. Pressure is controlled by a screw turned by hand to compress the spring. Only 10 pellets are placed in the tester, and pellet hardness is expressed in psi (Young, 1962).

Three major factors responsible for good quality of pellet feed:

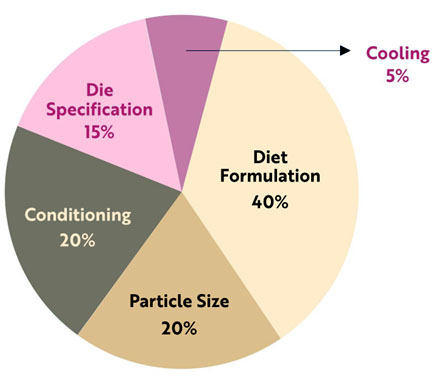

Formulation: Formulation plays a vital role in pellet quality but it is not the only factor. Ingredient composition like moisture percentage, fat percentage, protein percentage, starch content are important nutritional factors to be considered for good quality pellet production. Corn-soya diet is considered as the best formulation for getting better pellet quality. Dietary inclusion of 10-15% of wheat or wheat middlings or addition of as little as 5% sunflower oilcake will result in good quality pellets. It is found that addition of 1% oil in diet reduces pellet durability by 8-10%. Each 10% increase in fines is equal to about 0.016 kcal per kg reduction in energy. Moritz et al. (2002) stated that addition of two oils at graded levels (30 g/kg and 65 g/kg) in broiler diets and observed that PDI decreased from 81.6% to 62.1% with the highest oil inclusion.

Adding pellet binder in diet improves binding capacity and durability of pellet. There are several available options like synthetic polymer-based binder, natural resin-based binder, lignosulphonate and bentonite. But selection of best binder is very critical and should be based on higher pellet quality factor and mode of binding. Synthetic resin has pellet quality factor 40 and can irreversibly bind at high pellet temperature and conditioning moisture.

Processing equipment: Quality and die capacity are important for good quality pellet. Compression length and diameter of the compression hole are important factors for deciding the pellet quality. If thickness of the die increases, then pellet durability will improve but inversely throughput of pellet will decrease. So, trading off these two factors are very important. Similarly die set up, cooler set up and screen set up are deciding factors for good quality pellets.

Processing standard: As discussed earlier, grinding and pulverization during milling is another deciding factor for good quality pellets. In commercial broilers below 300-micron particle size during grinding helps in better gelatinization during conditioning resulting in a good durable pellet. Similarly standardizing the conditioning parameters like temperature, moisture percentage, steam injection and steam pressure, retention time are equally important. Briggs et al. (1999) stated that increasing retention time frame from 5 s to 15 s increased pellet durability by 4.5%.

Conclusion:

During processing, reduction of particle size is a significant influencing factor for better pellet quality and positively influences the performance of the birds. Formulation especially in terms of inclusion of certain feed ingredients are to be considered judiciously. Similarly standardization of processing equipment and process flow are equally important for pellet quality consistency.

Authors: Dr.Jayanta Bhattacharya- DGM(Techno Commercial) and Dr. Girish. C.H (Senior Technical Executive)

Bentoli AgriNutrition India Pvt., Ltd.

Reference: ❖ Abdollahi, M.R., Ravindran, V. and Svihus, B., 2013. Pelleting of broiler diets: An overview with emphasis on pellet quality and nutritional value. Animal feed science and technology, 179(1-4), pp.1-23. ❖ ASAE Standards. 2003. S269.4: Cubes, pellets, and crumbles – definitions and methods for determining density, durability and moisture content. St. Joseph, MI: ASABE. ❖ Briggs, J. L., Maier, D. E., Wakins, B. A., and Behnke, K. C. 1999. “Effect of Ingredients and Processing Parameters on Pellet Quality.” Poultry Science 78: 1464-71 ❖ Glover, B.G., Foltz, K.L., Holásková, I. and Moritz, J.S., 2016. Effects of modest improvements in pellet quality and experiment pen size on broiler chicken performance. Journal of Applied Poultry Research, 25(1), pp.21-28. ❖ Jensen, L.S., Merrill, L.H., Reddy, C.V. and McGinnis, J., 1962. Observations on eating patterns and rate of food passage of birds fed pelleted and unpelleted diets. Poultry Science, 41(5), pp.1414-1419. ❖ Lilly, K.G.S., Gehring, C.K., Beaman, K.R., Turk, P.J., Sperow, M. and Moritz, J.S., 2011. Examining the relationships between pellet quality, broiler performance, and bird sex. Journal of Applied Poultry Research, 20(2), pp.231-239. ❖ Maiorka, A., Magro, N., Bartels, H.A. and Penz Jr, A.M., 1998. Effect of sodium level and different relations between sodium, potassium and chloride in pre-initial diets on broiler chicken performance. Anais da XXXV Reuniao Annu. Soc. Bras. Zootec., SBZ, Botucatu, SP, Brazil, pp.478-480. ❖ Moritz, J.S., Wilson, K.J., Cramer, K.R., Beyer, R.S., McKinney, L.J., Cavalcanti, W.B. and Mo, X., 2002. Effect of formulation density, moisture, and surfactant on feed manufacturing, pellet quality, and broiler performance. Journal of Applied Poultry Research, 11(2), pp.155-163. ❖ Muramatsu, K., Massuquetto, A., Dahlke, F. and Maiorka, A., 2015. Factors that affect pellet quality: a review. Journal of Agricultural Science and Technology, 9(2), pp.717-722. ❖ Young, L.R. 1962. Mechanical durability of feed pellets. Unpublished MS thesis, Manhattan, Kansas: Kansas State University, Department of Grain Science and Industry.

Inaugurating the Center, the Minister for Animal Husbandry & Fisheries, Mr. Prabhu Bamala Chavan assured the poultry sector that he would help remove any hurdles in the growth of the sector. Commending the Center for investment in modern technologies, he said the contribution of animal husbandry and fisheries to the GDP was growing.

Inaugurating the Center, the Minister for Animal Husbandry & Fisheries, Mr. Prabhu Bamala Chavan assured the poultry sector that he would help remove any hurdles in the growth of the sector. Commending the Center for investment in modern technologies, he said the contribution of animal husbandry and fisheries to the GDP was growing.