In the summer season, as the temperature increases, poultry suffers from the condition called heat stress, also known as summer stress. This is a condition of imbalance between heat generation and heat loss in the body. This condition not only brings poor performance in birds but is also responsible for huge economic losses in terms of poor growth, lowered production, and higher mortality. This condition becomes a greater challenge when coupled with a high humidity environment, making the birds even more vulnerable. According to research, poultry is most  comfortable in an environmental temperature around 22-28°C (known as their thermoneutral zone). Once the temperature rises beyond this point, poultry show symptoms of heat stress: reduction in feed intake, poor growth, poor production, and increased mortality.

comfortable in an environmental temperature around 22-28°C (known as their thermoneutral zone). Once the temperature rises beyond this point, poultry show symptoms of heat stress: reduction in feed intake, poor growth, poor production, and increased mortality.

Technical Service Manager

Novus South Central Asia

In general, birds are susceptible to high environmental temperature due to an absence of sweat glands, their full body of feathers, their higher body temperature, and the fatty nature of the birds. This heat or summer stress not only brings lowered performance in poultry but also leads to immunosuppression issues, which can result in disease outbreaks and cause heavy mortality. This is mainly due to an absence of sweat glands in poultry making it impossible for them to dissipate heat. In this, males are found to be more prone to heat stress than females.

Ultimately, heat stress causes acid-base disequilibrium, or the inability to cool the body to maintain normal body temperature. Panting allows birds to release heat through an evaporative cooling kind of method, but high humidity coupled with high temperature causes insufficient panting to control body temperature resulting in heat stress.

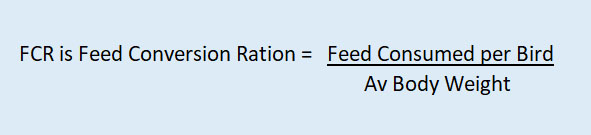

Behavioural, neuroendocrinal, and physiological changes are observed in birds during heat stress. Behavioural changes can include decreased feed intake, increased water intake, panting, less walking, and elevated wings. Physiological changes include oxidative stress, acid-base imbalance, and respiratory alkalosis. Internally the bird may experience decreased protein digestion and absorption, increased metabolic disorders, Increased chances of disease prevalence, and fertility issues. Production challenges can include reduced feed intake, poor feed conversion ratio, reduced body weight, impaired meat, and egg quality, and, as mentioned before, increased mortality.

Summer Poultry Management: The following steps can help birds combat heat stress

- Water management

- Housing management

- Feed management

- General management

Water management is crucial in heat stress management. In summer, water consumption goes up 3-4 times feed intake. So, a good quality water supply is essential. A water hygiene process must be followed because bad bacteria can prevail rapidly under poor conditions, which will lead to disease conditions. Water pipelines must be cleaned well and flushed with organic acids or hydrogen peroxide periodically. Treat water with a quality water acidifier and sanitizer. In general, try to make the water pH in acidic conditions (5.5-6). As feed intake is less during times of increased temperatures, nutritional water acidifiers should be used to help combat heat stress.

Housing management can be divided into two parts, inside shed management, and outside shed management.

- Thatching of the roof with green grass or agricultural waste can help reduce shed temperature. Paddy straw can be used for this purpose.

- Whitewashing the roof with lime helps mitigate the temperature inside the shed.

- Applying sprinklers above the shed.

- The use of gunny bags on the side walls (grill) of the shed over which drip water is set.

- Allowing trees to grow near the shed to provide shade on the shed.

- Prohibit wild birds, which can carry diseases like Avian Influenza, from entering the shed.

- Provide 4-6 feet of roof overhang to protect birds from direct sunlight.

- Provide ridge ventilation to help remove hot air from inside the shed.

Inside the shed

- Use of fans

- Use of a fogger

- Provide a continuous supply of cool water (if not possible, periodically flush the water to provide cooler water for birds)

- Reduce litter thickness (ideally around 400-450 grams per square foot)

Feeding Management

Research shows feed intake is reduced by 1.25% with every 1° rise in temperature. Further, it is observed that there is a decline in feed intake by almost 5% with every degree rise in temperature from 32-38° C. Knowing this it’s best practice to feed a good quality feed during times when heat stress can occur.

- Feeding should be done during the cooler hours of the morning or evening but too much gap in feeding time is not advisable.

- Increase the number of feeders and drinkers during feeding time to reduce competition among birds.

- Adding antioxidants is shown to be helpful to reduce stress and improve feed consumption while maintaining or improving body weight gain. (Vitamin E, Vitamin C, Selenium).

- A high-energy diet should be provided during summer because birds lose more energy while panting.

- Energy in feed should be supplemented with oil rather than grain because fat has the lowest heat increment value compared to carbohydrates and protein.

- Feed consumption is reduced in summer. To overcome nutritional and productive losses it is suggested to supplement the diet with 10-15% more amino acids, vitamins, and minerals rather than increasing the protein level directly.

- Increase calcium and phosphorus levels to overcome thin eggshells more often seen during summer due to respiratory alkalosis (more carbon dioxide is lost due to panting).

- Instances of viral challenges increase during this time as immunosuppression is common. Fumaric acid is shown to have good antiviral properties and can help to reduce viral challenges. A combination of coated benzoic acid and fumaric acid as an acidifier (as AVIMATRIX® feed supplement) can help to reduce stress and improve the performance of the flock.

- MINTREX® chelated trace minerals, a supplement of organic trace minerals zinc, copper, or manganese, and methionine source HMTBa are shown to help heat stress conditions. HMTBa molecules undergo absorption through diffusion, which doesn’t require energy. Thus, using minerals with HMTBa can reduce heat stress during summer and help improve performance.

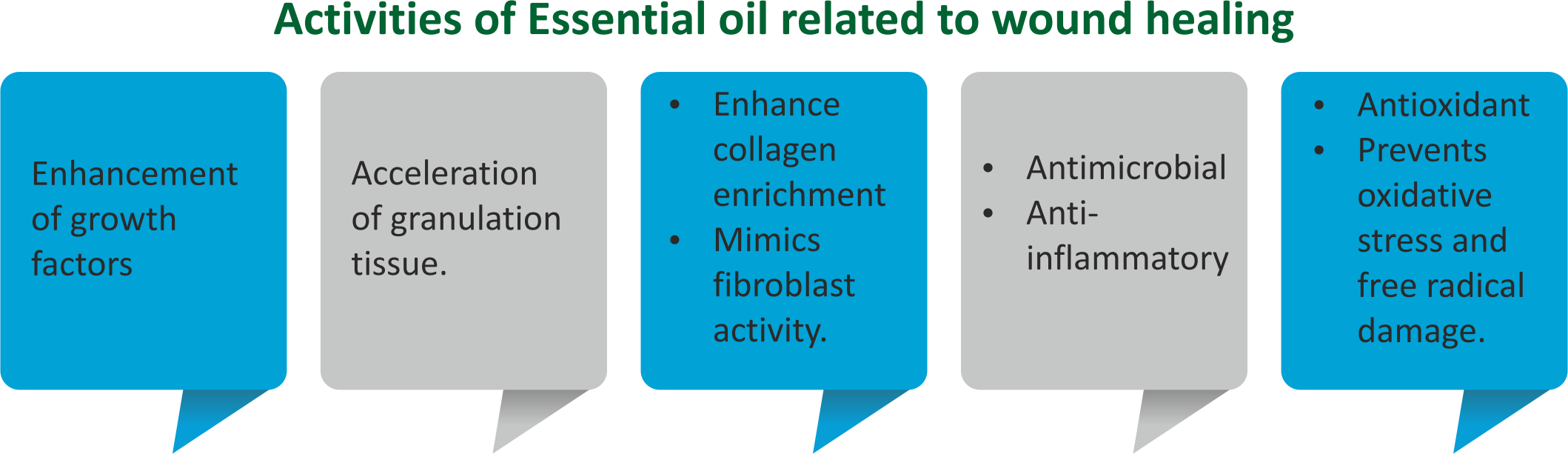

- Essential oils have a broad range of action from being immunomodulators to performance enhancers. Adding essential oils – especially thymol and carvacrol – to the diet can help mitigate summer stress challenges and improve meat yield and overall performance.

- Use of MOS and B Glucans during heat stress conditions is convincing due to the possibility to reverse or compensate physiological alterations induced by heat stress and by restoring immune function and promoting robust inflammatory responses.

- The addition of ammonium chloride, potassium chloride, and/or sodium bicarbonate has shown improved performance in broilers by improving water quality and feed intake.

- Probiotics can be used to help control the corticosterone level and the excessive release of pro-inflammatory agents. Lactobacillus-based probiotics enhance goblet cell count in the duodenum and jejunum of heat-stressed broilers thereby improving the feed conversion ratio.

- Since a hot humid climate favors the growth of mould/fungi in feed the consistent use of an antifungal is recommended.

General Management

- The depth of litter should be 2-3 inches on the floor.

- 10% extra floor space should be provided in summer. Bird overcrowding only contributed to heat stress and must be avoided.

- Shifting, transportation, debeaking, and vaccination should take place during the night or cool hours in the morning.

- Birds severely heat stressed may be dipped in cold water for 2-3 minutes to provide relief. Be sure to keep their head and neck above the water level.

- Use foggers in the shed, which can reduce the shed temperature up to 5-10°C depending on the quality of the fogger.

The house should be situated away from other buildings to facilitate the free movement of air.

“Summer management is crucial not only to improve the performance but to gain profit in adverse conditions. So, effective use of feeding, Water, shed management brings the good health of birds and thereby profit to the farmer”.

Right to Protein

Right to Protein