PRANAV BiTEK AgroTech Pvt. Ltd., a South African joint venture is hiring National Sales Manager, to be based out of Pune.

Interested candidates can send the resume at hr@pranavbitek.in or call +91 96654 20559.

PRANAV BiTEK AgroTech Pvt. Ltd., a South African joint venture is hiring National Sales Manager, to be based out of Pune.

Interested candidates can send the resume at hr@pranavbitek.in or call +91 96654 20559.

CHESTERFIELD, MO (September 5, 2024) – A new director at NOVUS is driving innovation at the intelligent nutrition company.

Gaurav Shah recently joined NOVUS as the new associate director of innovation and business development. He is responsible for routing Novus’ innovation pipeline and strategy in the newly created role.

Gaurav Shah recently joined NOVUS as the new associate director of innovation and business development. He is responsible for routing Novus’ innovation pipeline and strategy in the newly created role.

“While we’re working internally on new projects, services and solutions, we know there is a whole world of innovation beyond our labs,” says Associate Vice President of Global Strategic Marketing, Technology and Innovation Abishek Shingote. “It’s not enough for us to say we will be innovative; we have to do it. Gaurav’s focus is on business development that will drive new growth and support our customers globally.”

At NOVUS, Shah is updating the company’s innovation capabilities by leveraging its open innovation model.

“Something that can slow down innovation is being stuck in your competencies or feeling the need to fully own new competencies before developing something,” Shah says. “With open innovation, the goal is to work closely with start-ups, universities, established companies, and even customers that are already competent in what we want to do. We’re joining forces with those partners to deliver value to the industry.”

Understanding that new ideas, technology and services can come from many different places, Shah says NOVUS is looking for partnerships that match its strategic interests: animal nutrition and health feed additives that lead to better performance.

“NOVUS has a good track record of delivering disruptive technology – like the first liquid methionine, the first bis-chelated trace minerals, and now embedding functional additives in corn kernels with INTERIUS™ technology,” he says. “So, finding partners that can help us deliver something new through INTERIUS™ technology is certainly a goal.”

Shah says for NOVUS innovation is not a “good to have” it’s a “need to have” and that the new open innovation platform coupled with his efforts to connect the company to external partners will mean big things for customers and the feed additive industry in the years to come.

“The fact that we’re investing in new and expanded technologies and that we’ve created a very clear structure to evaluate ideas and partnerships and bring products to market shows NOVUS is serious about innovation. We’re ready to talk with others who are too.”

Shah comes to the leader in intelligent nutrition after serving as business development manager for BioResource International, Inc. (BRI), and as global director of the feed digestibility category at Adisseo. His education includes a master’s degree in microbial biotechnology from North Carolina State University (U.S.) and a post-graduate degree in patent law and intellectual property.

To learn more about NOVUS and to contact Gaurav about partnership opportunities, visit novusint.com.

EuroTier, the world’s leading trade fair for professional animal husbandry and livestock management will take place from November 12 to 15, 2024 at the exhibition grounds in Hanover, Germany. EnergyDecentral, the leading international trade fair for decentralized energy supply and the Inhouse Farming – Feed & Food Show both take place in parallel with EuroTier. The EuroTier exhibition and its technical programme, is organized by the DLG (German Agricultural Society). Under the guiding theme “We innovate animal farming”, the innovation platform for the global livestock industry offers an array of conferences and evening events. These include the International Poultry Day 2024 with the Poultry Event in the evening. Entry tickets can now be purchased in the online ticket shop: https://www.messe-ticket.de/DLG-SHOP/ET24/Shop

Even before the official start of the trade fair, the poultry sector will take centre stage at EuroTier with the “International Poultry Day“. It will kick off on 11 November at 3.30 pm with the International Poultry Conference in the Convention Center of the exhibition grounds.

Under the motto “Poultry for a healthy planet”, keynote speeches on sustainable poultry farming will take centre stage, including on the topic of carbon footprint. The subsequent panel discussion will focus on the development prospects of the international poultry industry. The central question is: “What is a sustainable poultry industry?” Renowned speakers and industry experts will shed light on various aspects of this topic and highlight possible solutions:

· What role do poultry meat and eggs play against the backdrop of rising global consumption of poultry meat and eggs?

· How sustainable is the poultry industry today?

· What can be done to further reduce the carbon footprint of the production chain while remaining economical and efficient?

An all-round view of feeding

As a central topic in livestock farming, feeding occupies the largest exhibition area at EuroTier. Feeding topics and trends can be further explored on all Expert Stages in the technical programme. At the DLG stand, farming professionals can access the new online searchable collection of feedstuffs and gain insight into the properties and nutrient content of around 1,300 feedstuffs.

Additionally, the direct sales of farm products is becoming increasingly important for consumers as it guarantees transparency and freshness. The topic “Direct farm sales and on-farm slaughtering” at EuroTier will focus on mobile slaughtering and highlight its central role in the farm sales of agricultural products.

The ticket shop for EuroTier 2024 is open. EuroTier has several travel partners in India that will be happy to assist with further information regarding the 2024 event. If of interest, please visit the EuroTier website for a list of all partners. Further details and tickets can be found on the website: www.eurotier.com

Read More: EuroTier 2024 Curtain Raiser

“Great visitor interest in animal welfare, sustainability and automation.”

EuroTier 2024, scheduled from November 12 to 15 in Hanover, Germany, is the world’s leading trade fair for professional animal farming and livestock management. DLG (German Agricultural Society), a non-profit organization that supports the facilitation of farming knowledge, is in charge of organizing the trade show. The exhibition attracts some 2,100 companies including this year 15 from India and 120,000 visitors. Additionally, several delegations from India are expected.

We asked Ines Rathke, EuroTier Project Manager, what innovations visitors can expect and how the trade fair supports farmers in tackling current challenges.

Poultry TRENDS: Mrs Rathke, the main theme of this year’s EuroTier is “We innovate animal farming”. Why did you finally decide on this motto?

Poultry TRENDS: Mrs Rathke, the main theme of this year’s EuroTier is “We innovate animal farming”. Why did you finally decide on this motto?

Ines Rathke: With the theme “We innovate animal farming“, we as the DLG would like to emphasize that challenges are always also opportunities. Climate change, increased environmental regulations and changing social demands on agriculture… with the relevant innovations and solutions, this can also mean progress for agriculture. The key question for us as organizers is therefore: “How can we help livestock farmers find the answers to the questions of tomorrow that continue to not only ensure food security but also secure their farms in the long term?”. And this is exactly where this year’s main theme comes in. At EuroTier 2024, visitors will be able to inspect innovations for modern animal husbandry, animal housing construction, feeding technology and automation, among many other novel professional approaches.

Poultry TRENDS: What special features can visitors look forward to?

Ines Rathke: The launch of our new platform for livestock robotics, digitalization, automation and AI in agriculture should be particularly interesting this year: FarmRobotix. The popular “Barn Robot Event” is integrated into FarmRobotix. Here, farming professionals can experience seven different automatic feed pushers in action. Farm businesses continue to benefit from automating farm processes with robots, which then frees up time to further optimize other operations.

Another highlight of the trade fair is the DLG Spotlight “AI on poultry farms“. In a dedicated exhibition area, start-ups and established companies will be presenting their AI-based solutions for poultry farming, from in-ovo sexing to animal welfare and health monitoring.

Poultry TRENDS: Agriculture is facing major challenges: increasing environmental regulations, structural change, growing animal welfare requirements versus increasing efficiency in global competition. What ideas will EuroTier provide farmers with?

Ines Rathke: The exhibiting companies at EuroTier will present solutions for all livestock sectors. The “World Poultry Show” is back at EuroTier and is preceded by “International Poultry Day 2024“, an invitation event that will take place the day before EuroTier starts on November 11 at the EuroTier exhibition grounds, renowned speakers and industry experts will address the topic of “Poultry for a healthy planet”. Which screws can be turned to further reduce the CO2 footprint of the production chain while remaining economical and efficient are just some of the questions discussed. A total of 300 of our exhibitors specialize in poultry. And the DLG spotlight “Inhouse Farming” is all about self-contained agricultural and food systems including a focus on insects. Additional topics are aquaculture and vertical farming in circular economy systems. Animal nutrition is a major lever for greater animal welfare, animal health and efficiency on the farm. Farmers can start here easily and without major new investment and will find plenty of inspiration and new ideas for the future in three large halls at EuroTier.

Poultry TRENDS: The shortage of skilled workers is omnipresent. What does EuroTier have to offer to help people find a job?

Ines Rathke: Whether young professional or young farmer , there is also a lot on offer for young people at EuroTier. On Wednesday (November 13), “Celebrate Purpose” (from 5 p.m. at DLG stand 13-E58) will show the diverse and meaningful opportunities to get involved in agriculture and whet the appetite for the industry.

Thursday (November 14) is Young Farmers Day. This is the central meeting place for all those at the beginning of their career in agriculture and agribusiness. At the “Young DLG Lounge“, stand 13- E58, interested visitors can find out what the agricultural industry has to offer young professionals. The specialist program offers guidance on career topics and the Career & Networking Events “YoungFarmersConnect” brings interested parties together with companies between 4 and 7 p.m. at DLG Stand 13-E58 for a relaxed get-together and exchange.

Poultry TRENDS: EnergyDecentral – the leading trade fair for decentralized energy supply – and the Inhouse Farming – Feed & Food Show will take place at the same time as EuroTier 2024: How do the three themes fit together?

Ines Rathke: The Inhouse Farming – Feed & Food Show will present new and complementary mainstays for farms. Above all, the show presented for first time at EuroTier will focus on the opportunities offered by vertical farming, the provision and use of alternative proteins and the use of aquaculture, aquaponics and the cultivation of algae. EnergyDecentral is the leading trade fair for decentralized energy supply. The focus here is on the generation of renewable energy on the farm, including biogas plants and solar energy but also wood fuel and wind turbines. Both trade fairs are the ideal complement to EuroTier 2024.

Poultry TRENDS: How has the industry responded to EuroTier 2024 so far?

Ines Rathke: The response so far has been very good. A visitor survey that we conducted at the end of June already showed a high level of interest in visiting the trade fair. 60 percent of those surveyed stated that they intended to visit EuroTier in Hanover. When it comes to current industry topics, professional farming visitors from both Germany and abroad rank high the topics of animal welfare, sustainability, automation, robotics and digitalization. Around 2,000 exhibitors will be showcasing their innovations and offerings here, making EuroTier unique in its size and diversity.

EuroTier the world’s leading trade fair for professional animal husbandry and livestock management, will take place from 12 to 15 November 2024 in Hanover, Germany. Some 2,100 companies and organizations from 55 countries will be present. Under the guiding theme “We innovate animal farming.” the trade fair offers an international technical program on – among others – the latest developments in dairy and poultry production.

A few months before kick-off, interest in the EuroTier / EnergyDecentral 2024 trade fairs is already high among visitors. In a survey (carried out in June 2024) of potential professional farming visitors to the world’s leading trade fair for professional animal husbandry and livestock management, 60 percent of respondents stated that they have already made firm plans to visit EuroTier in Hanover, Germany. Some 30 percent responded that they will be making a decision in the coming weeks. The exhibition areas of stabling and feeding technology as well as feed input and operating resources were particularly highly rated. When it comes to current industry topics, visitors prioritize animal welfare, sustainability, digitization, automation and robotics.

A few months before kick-off, interest in the EuroTier / EnergyDecentral 2024 trade fairs is already high among visitors. In a survey (carried out in June 2024) of potential professional farming visitors to the world’s leading trade fair for professional animal husbandry and livestock management, 60 percent of respondents stated that they have already made firm plans to visit EuroTier in Hanover, Germany. Some 30 percent responded that they will be making a decision in the coming weeks. The exhibition areas of stabling and feeding technology as well as feed input and operating resources were particularly highly rated. When it comes to current industry topics, visitors prioritize animal welfare, sustainability, digitization, automation and robotics.

Robotics in livestock farming

Robot-assisted automation for animal husbandry is developing fast with many new applications now available. Farm managers are actively employing these technologies to increase productivity while reducing costs and combating rising shortage of skilled labor. Ultimately, this leads to improved working conditions as well as enhanced animal welfare, animal health and benefits to the environment. This ties in with the maxim ‘We innovate animal farming’, the chosen theme for EuroTier 2024 exhibition. Farming professionals will be looking forward to the DLG’s new platform for robotics, digitization, automation and AI in agriculture: FarmRobotix. At the Barn Robot Event seven feed pusher robots for dairy cattle barns will be presented as part of daily live demonstrations in a dedicated area.

World Poultry Show

The World Poultry Show is the international platform for the poultry industry. Exhibitors along the entire production chain can be found in Halls 16, 17 and 23. The DLG spotlight “AI in poultry farming” is presenting solutions for the practical use of AI-supported technologies for the poultry industry and the Poultry Expert Stage, invites visitors to attend numerous top-class specialist presentations on all aspects of poultry production. Scientists, consultants, staff from funding projects and other international industry experts will be presenting innovative approaches.

Showcase for innovative animal feed solutions

In the debate about securing food for a growing world population, animal feed is an increasingly important topic. In the future, feedstuffs that are not in direct competition with human food will be prioritized. Livestock farmers can already now reduce the amount of land required for feed cultivation by actively applying efficient feed management measures. Protein sources that can replace rapeseed and soya and other conventional feedstuffs are increasingly viewed as an attractive alternative.

In the debate about avoiding food competition, possible alternative sources of protein, fat and carbohydrates for animal feed have entered the discussion. One area is the use of insects as animal feed. Another alternative food source under consideration is plant biomass from aquatic sources, especially algae, which do not require agricultural land.

In the debate about avoiding food competition, possible alternative sources of protein, fat and carbohydrates for animal feed have entered the discussion. One area is the use of insects as animal feed. Another alternative food source under consideration is plant biomass from aquatic sources, especially algae, which do not require agricultural land.

EuroTier 2024 reflects the developments in this area and presents the latest alternative protein sources at the “Inhouse Farming – Feed & Food Show” for the self-contained agricultural and food systems of the future. Additionally, at EuroTier 2024, leading companies from the national and international animal feed industry and start-ups will be demonstrating how innovative feed and processes can be used to meet the demands of responsible livestock feeding.

DLG-Spotlights to explore practical farming topics

• The TopTierTreff feature is once again the international marketplace for top genetics in Hall 11, where leading German and international breeding companies and organizations from the dairy and beef cattle sector will present breeding stock.

• The “Solar Transition” spotlight at EnergyDecentral 2024, which takes place in parallel to EuroTier, and the “Inhouse farming” spotlight with a focus on alternative proteins and indoor farming solutions.

• The “agrifood start-ups” area presents innovative industry solutions from entrepreneurial companies while working as a networking venue for start-ups and investors.

• In the DLG.Prototype.Club, teams of software engineers solve technical challenges set by exhibitors in order to develop workable prototypes for their initiatives.

The topics sustainability, animal welfare and environmental protection – from field to plate – will be addressed and brought to life at the DLG-stand in hall 13. Exhibits on reducing emissions in and around the housing and the DLG animal welfare program for dairy cattle farming are also showcased.

Award-winning innovations – inspiring people

As part of EuroTier, the DLG will be presenting three leading international awards for innovative animal husbandry technology:

The “Innovation Award EuroTier” recognizes innovations ready for practical farm use and underlines the importance of modern technical solutions for livestock farming. The “Animal Welfare Award“, a distinction of the EuroTier Innovation Awards, recognizes products and services that meet the requirements for higher animal welfare standards and improved animal health to a particularly high degree. Pioneering work and concepts for sustainable animal husbandry and decentralized energy production are honored with the “DLG-Agrifuture Concept Winner Award“, evaluated by an international jury. The international “Women in Ag Award” honors inspiring women from agriculture, agribusiness, education, technology and research. The best channels from YouTube, TikTok, Facebook and Instagram will receive the “DLG Agri Influencer Award“.

Optimal complement: EnergyDecentral and Inhouse Farming

EnergyDecentral trade fair and the Inhouse Farming – Feed & Food Show both take place in parallel with EuroTier. Covering the entire value chain of sustainable energy production, including resources, energy production and smart energy, EnergyDecentral has already established itself as the leading platform for decentralized energy supply. The new Inhouse Farming – Feed & Food Show will be the global B2B venue for agricultural and food systems of the future. Closely networked with agricultural practice, the Inhouse Farming – Feed & Food Show offers specialist information, perspectives, innovations and business – from feed to food. Both offerings represent an optimal extension of the specialist range of topics at EuroTier.

Ticket shop now open and travel information

The ticket shop for EuroTier 2024 is open. EuroTier has several travel partners in India that will be happy to assist with further information regarding the 2024 event. If of interest, please visit the EuroTier website for a list of all partners. Further details and tickets can be found on the website: www.eurotier.com

Author:

Meghana Mukherjee Salvi,

Director, Glamac International

Poultry TRENDS Editorial Board Member

On 23rd July 2024, Union Finance Minister Nirmala Sitaraman presented the BJP-led NDA government’s first budget after its re-election in June. The clock struck 11:00 AM, and the nation was abuzz with anticipation. The budget frenzy was palpable, with the stock market in flux, public discourse at its peak, and the media providing extensive coverage. Investors, businessmen, and the workforce were all part of this moment, closely monitoring the budget speech and dissecting the proposed policies to gauge the impact on their respective sectors.

Homing in on the prospects of agriculture, women and farmer welfare, employment, skill generation, manufacturing, and infrastructure, the Union Budget 2024 has marked the cornerstone for ‘Vikshit Bharat 2024’. As the Indian poultry sector steps into the limelight with a projected CAGR of 8.1% between 2024-2032, it becomes crucial to decipher the budget’s implications.

This article is a deep dive into the budget, offering insights into its impact on the Indian poultry sector.

Let’s explore what the future holds for the poultry industry and whether the budget has successfully met the sector’s expectations.

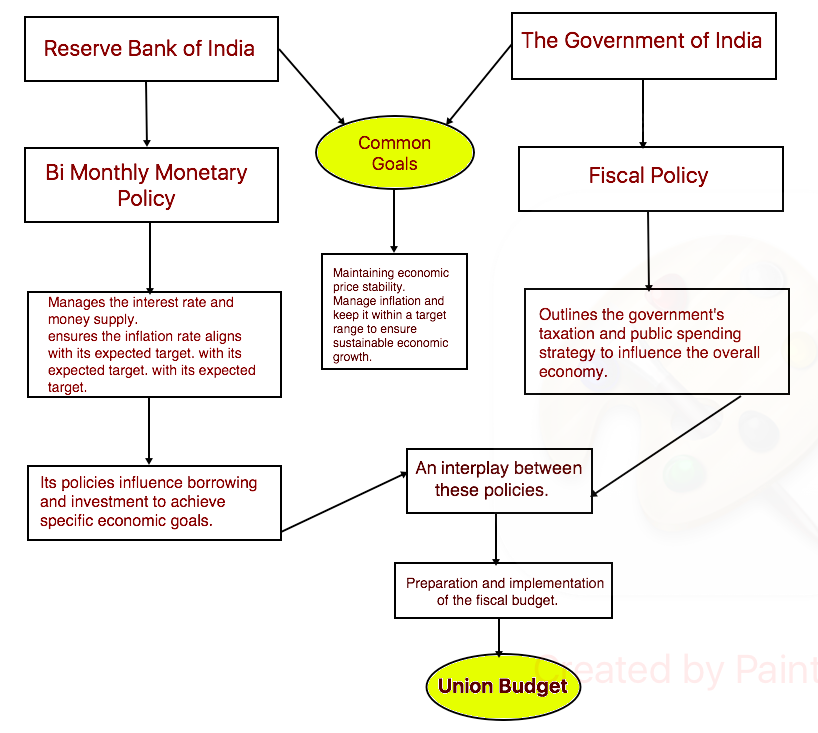

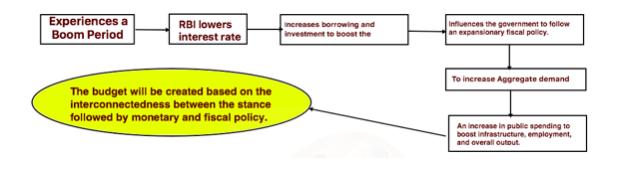

What is a Budget? An Interplay between Monetary and Fiscal Policy

Therefore, it’s crucial to highlight the inflation rate in the Union Budget. Sharing the inflation rate is significant as it helps businesses, consumers, and policymakers decide where to invest their money, when to spend it, and how much should be left in reserve. It’s also a way of evaluating how well current fiscal and monetary policies work towards curbing inflation and what additional steps must be considered for future stability.

Pre-Budget Expectations: Poultry Industry’s Bucket List

Over the decades, the poultry sector has witnessed staggering heights and is slated for an illustrious growth trajectory. However, the industry is often subjected to challenges such as raw material shortages, price instability, infrastructural bottlenecks, and insufficient government impetus. Recently, the industry has garnered long-awaited central focus, and they haven’t shied away from voicing their opinions and expectations from the Union Budget. Let us have a look at their key demand areas.

1. Expects measures to boost maize supply, a critical ingredient in poultry feed. (Current maize production is 36 MMT and expected requirement is 41 MMT including ethanol production.)

2. Price stability of raw materials like maize and soybean.

3. Import liberalisation (Zero Duty) on corn and wheat will alleviate the sector’s production costs. (Corn prices are rising due to the extended demand of the poultry sector and ethanol manufacturers.)

4. Import of genetically modified (GM) corn and soybean meal should be permitted.

5. Establishing cold storage infrastructure at the retail levels. (Reduce price volatility and increase farmer profitability)

6. Import duty reform for the edible oil sector.

7. Develop a dedicated body to promote chicken and egg exports.

8. Implementing a stringent ban on antibiotic growth promoters in poultry. (Improves animal welfare, product quality and international acceptability.)

9. Reduce the current 18 per cent tax on biosecurity products.

10. Continue the ban on future trading of soybean and its products in NCDEX.

Budget 2023: A Quick Recap

The aftermath of Budget 23 had ramifications, and the poultry industry is still reeling. To get the complete gist of the current budget, let’s turn back the pages to the key highlights that impacted the poultry industry last year.

Breaking Down the Budget’23 – Poultry feed constitutes nearly 70% of the production cost. The industry has witnessed extreme shortages in essential raw materials, leading to staggering price hikes. It has led to a shot up in production costs, yet price recovery has been dismal. There is a massive gap between the farm gate prices of poultry products and their retail prices. This highlights that farmers are not receiving fair prices and face immense losses. Thus, a solution to stabilize the availability of raw materials holds precedence. The ethanol policy creates a further dent in maize availability. Though the budget incentivizes infrastructure development, it will likely span over some time. Thus, the effects will only be felt with a time lag. Lastly, promoting the export of Indian poultry products opens the door to a vast global market; it should be pursued after strengthening production and satisfying a growing domestic demand.

Budget 2024: A detailed Overview

The budget for 2024 included multiple key proposals that significantly impact the poultry sector. Let’s examine each of the proposed recommendations and understand its plausible implications.

Solidifying Raw Materials (Pulses & Oilseeds)

Securing the availability of key raw materials like maize and soybeans is essential to streamlining the poultry supply chain and stabilizing the sector.

What the Budget Proposes

• To achieve self-sufficiency in pulses, an ‘Atmanirbharta‘ strategy is being implemented to strengthen production, storage, and marketing for oilseeds such as sesame, soybean, mustard, groundnut, and sunflower.

• A large-scale vegetable production cluster will be developed closer to major consumption areas. The cluster aims to integrate Farmer-Producer Organisations (FPOs), cooperatives, and start-ups.

• There is a provision of ₹1.52 lakh crore for agriculture and allied sectors. This includes those growing critical raw materials like maize and soybeans.

• Developing cold storage facilities and improved infrastructure will curtail losses and boost the supply of quality produce.

• Exemption of basic customs duty and AIDC on crude soybean oil imports and sunflower seed oil.

Interpretation—These measures collectively strive to improve key raw material availability. They are incentivizing the farmers to increase production and also easing imports to meet the domestic shortage. These steps should arrest the current shortage of maize and soybeans and stabilize prices in the long run.

Enhancing Export Competitiveness

Focusing on infrastructure, market access, and product quality is imperative for Indian produce to meet global standards.

What the Budget Proposes

• A proposed budget of ₹11,11,111 crore for capital expenditure.

• Significant funds to enhance cold storage and logistics infrastructure.

• No custom duty on mineral and vitamin premixes.

• Credit Guarantee Scheme for MSMEs in the manufacturing sector. It includes MSMEs producing poultry equipment, feed, and medicines. From facilitating term loans for the purchase of machinery and equipment, pooling credit risks, self-financing guarantee cover-up of ₹100 crore, and continuation of bank credit during stress periods, the budget has an expansive proposal for boosting MSMEs.

Interpretation—Logistics and cold storage facilities are central to ensuring poultry produce is transported with minimal losses and without affecting product quality. Adequate cold storage facilities ensure increased shelf life for poultry products and maintain quality. With the proposed CapeX, state-of-the-art processing units and storage facilities may be developed.

Poultry Industry: The Road Ahead

Agricultural infrastructure, customs relaxation, and crop production are expected to positively impact the availability and affordability of essential raw materials for poultry feed, such as maize and soybean. In view of these suggestions about the poultry industry, there seems to be a ray of hope in terms of addressing challenges related to raw material availability, price stability, and export facilitation.

The Union Budget 2024 rightly acknowledges the challenges the poultry sector is facing. While it may have fulfilled only some of the sector’s demands, it has recognized this economic player’s significant contribution to the national GDP. The Budget aligns with the industry’s expectations, demonstrating a clear commitment to promoting sustainability and development. This recognition and commitment should instil a sense of optimism in the industry’s stakeholders about the poultry sector’s future.

Despite these steps, competition remains an uphill task for this sub-sector if it is to gain more ground. Poor maize production, among others, such as the need for quality domestic meat and egg products, new market creation, and improvements in transport systems, are some issues that ail them today. These challenges are necessary for its consolidation in the market and gaining sustainability. Still, by proposing these measures, India’s Union Budget 2024 betrays intentions to address its concerns and priorities over Indian poultry, potentially unlocking developmental opportunities among other stakeholders for India’s long-term prosperity.

EuroTier is the leading international trade fair for professional animal farming and livestock management. Once again, the “World Poultry Show” is part of the event. Among others, the theme spotlight Artificial Intelligence “AI in the poultry house” will present solutions for poultry housing. Additionally, the poultry sector will take centre stage at EuroTier with the “International Poultry Day”.

“We innovate animal farming” is the guiding theme of this year’s EuroTier, the world’s leading trade fair for professional animal husbandry and livestock management, 12-15 November, 2024, held in Hanover, Germany.

“We innovate animal farming” is the guiding theme of this year’s EuroTier, the world’s leading trade fair for professional animal husbandry and livestock management, 12-15 November, 2024, held in Hanover, Germany.

Organized by the DLG (German Agricultural Society), EuroTier will once again be the central venue for international farmers, contractors, distributors and other experts from science and practice. Key focus areas include animal welfare, animal health, sustainability, emission reduction, breeding, livestock management, feeding, digitalization, farm management, processing and marketing. The international poultry industry will be joining the World Poultry Show, once again held at EuroTier.

World Poultry Show returns to EuroTier 2024

Conferences and events within the World Poultry Show offer international poultry professionals a wide range of opportunities for networking and professional exchange and information. The main topics will be animal welfare and the CO2 footprint in poultry.

The theme spotlight Artificial Intelligence “AI in the poultry house” aims to highlight the possibilities of the constantly advancing developments in the field of automation and digitalization in poultry farming and illustrate them with examples. At the special area, start-ups and established companies will present their AI-based solutions for poultry farming, from in-ovo sex determination to animal welfare and health monitoring. Practical solutions for management and technology on livestock farms and in upstream areas will provide ideas for further development for the benefit of humans and animals. Additionally the Expert Stage “Poultry” will provide information on current developments and innovations in the areas of poultry farming, animal health, feeding, management and marketing.

International Poultry Day 2024 – Poultry for a healthy planet

Even before the official start of the trade fair, the poultry sector will take centre stage at EuroTier with the “International Poultry Day”. It will kick off on 11 November at 3.30 pm with the International Poultry Conference in the Convention Center of the exhibition grounds.

Under the motto “Poultry for a healthy planet”, keynote speeches on sustainable poultry farming will take centre stage, including on the topic of carbon footprint. The subsequent panel discussion will focus on the development prospects of the international poultry industry. The central question is: “What is a sustainable poultry industry?” Renowned speakers and industry experts will shed light on various aspects of this topic and highlight possible solutions.

Under the motto “Poultry for a healthy planet”, keynote speeches on sustainable poultry farming will take centre stage, including on the topic of carbon footprint. The subsequent panel discussion will focus on the development prospects of the international poultry industry. The central question is: “What is a sustainable poultry industry?” Renowned speakers and industry experts will shed light on various aspects of this topic and highlight possible solutions.

Further details and tickets can be found on the website www.eurotier.com

Dr. K N Reddy, CEO of Natural Remedies and a leading figure in animal healthcare, has been awarded an honorary Doctorate in Poultry Science by the esteemed European International University. With over 30 years of expertise, Dr. K N Reddy has transformed Natural Remedies into a global leader in Phytogenic solutions for animal health.

Dr. K N Reddy, CEO of Natural Remedies and a leading figure in animal healthcare, has been awarded an honorary Doctorate in Poultry Science by the esteemed European International University. With over 30 years of expertise, Dr. K N Reddy has transformed Natural Remedies into a global leader in Phytogenic solutions for animal health.

Under his leadership, Natural Remedies has expanded its reach to 45 countries, contributing significantly to the US Pharmacopeia, British Pharmacopoeia, and Indian Pharmacopoeia. Dr. K N Reddy’s innovative strategies have driven the company’s growth and commitment to sustainable, nature-based healthcare solutions.

Hailing from Warangal, Dr. K N Reddy embraced his journey by pursuing a bachelor’s degree in Poultry Science from Kakatiya University. His dedication and vision have since led to groundbreaking contributions in the field.

As an EC Member of CLFMA and chairholder for various poultry boards, Dr. K N Reddy advocates for continuous learning and innovation. His leadership has been instrumental in positioning Natural Remedies as a pioneer in developing safe, effective, and sustainable Phytogenic solutions.

Dr. K N Reddy’s mantra, “Ordinary people with extraordinary commitment can produce outstanding results,” encapsulates his approach to leadership and innovation. His contributions continue to shape the future of poultry health and animal healthcare globally.

Natural Remedies is a Phytogenic solution provider globally for Animal & Human health, committed to sustainability, aiming for carbon neutrality, waste elimination, and recycling within the next decade. The company’s core value of “Being Useful” underscores its mission to positively impact the environment and promote health and happiness through science and nature.

To know more, scan the QR code

Contact Details:

Sushant Datta

General Manager (Marketing) – Natural Remedies Private Limited

Phone @ + 91 72085 09559

Email- @ sushant.d@naturalremedy.com

The upcoming EuroTier (November 12-15 2024, Hanover, Germany) is again garnering significant attention from global players in the animal farming and livestock management sectors. With an impressive count of over 2,000 exhibitors already confirmed from 51 countries, the event is poised to reach pre-pandemic levels, as reported by the DLG (German Agricultural Society), the event’s organizer.

EuroTier maintains the status of the world’s leading trade fair for animal farming, offering both the largest number of exhibitors and the most comprehensive technical program.

EuroTier maintains the status of the world’s leading trade fair for animal farming, offering both the largest number of exhibitors and the most comprehensive technical program.

A major highlight of EuroTier 2024 is the World Poultry Show, featuring leading companies in the poultry sector and showcasing the latest advancements in poultry farming. Parallel events further enhance the breadth and depth of offerings at EuroTier. Such as Energy Decentral, focusing on decentralized energy generation, and Inhouse Farming, the Feed and Food Show, position EuroTier as a pivotal event driving innovation, collaboration, and progress in the animal farming and energy sectors.

The presence of numerous country pavilions from prominent nations underscores the event’s international stature. Pavilions from Canada, China, Finland, France, South Korea, USA are already confirmed.

The presence of numerous country pavilions from prominent nations underscores the event’s international stature. Pavilions from Canada, China, Finland, France, South Korea, USA are already confirmed.

Under the overarching theme “We innovate animal farming,” EuroTier 2024 will spotlight technical solutions and industry standards across multiple livestock sectors, including cattle, pigs and poultry. Additional topics such as sheep, goats, equine management, aquaculture, alternative proteins, and direct farm sales will also feature prominently, reflecting the comprehensive nature of the exhibition.

The technical program at EuroTier 2024, developed in collaboration with industry partners, promises a robust lineup of events and conferences addressing key issues in the livestock sector. From specialized sessions like the “TopTierTreff” for live cattle breeds on rotating stage to thematic spotlights such as “AI in the poultry house” attendees can expect a wealth of insights and networking opportunities.

The technical program at EuroTier 2024, developed in collaboration with industry partners, promises a robust lineup of events and conferences addressing key issues in the livestock sector. From specialized sessions like the “TopTierTreff” for live cattle breeds on rotating stage to thematic spotlights such as “AI in the poultry house” attendees can expect a wealth of insights and networking opportunities.

Five months before kick-off, interest in the EuroTier / EnergyDecentral 2024 trade fairs is already high among visitors. 1,250 respondents from both Germany and abroad took part in the online survey. 60 percent of potential professional farming visitors stated that they have already made firm plans to visit EuroTier in Hanover, Germany. Some 30 percent responded that they will be making a decision in the coming weeks. 1,250 The exhibition areas of housing and feeding technology as well as feed input and operating resources were particularly highly rated. When it comes to current industry topics, visitors from ranked as most interesting animal welfare, sustainability, automation, robotics and digitalization.

Further details can be found on the website www.eurotier.com. DLG, the organizer cordially invites you to EuroTier 2024 to explore the myriad opportunities which will be available on side. All interested parties are kindly advised to start preparing for travel to Hanover, Germany.

Further details can be found on the website www.eurotier.com. DLG, the organizer cordially invites you to EuroTier 2024 to explore the myriad opportunities which will be available on side. All interested parties are kindly advised to start preparing for travel to Hanover, Germany.

About DLG:

DLG, with over 31,000 members, is a non-profit organization fostering agricultural innovation globally. Through its subsidiary DLG International and a network of 3,000 experts, DLG organizes 30+ regional agricultural exhibitions worldwide. EuroTier and Agritechnica, DLG’s flagship events in Hanover every two years, drive international collaboration in livestock and agricultural machinery. Headquartered in Frankfurt, DLG conducts trials at sites like the International Crop Production Centre and the DLG Test Centre, promoting practical insights. With 40+ working groups spanning farmers, academics, and industry, DLG bridges theory and practice in areas like irrigation and precision farming.

AB Vista, a leading global supplier of innovative feed ingredients and technical services, has announced the appointment of Mr. Atmaram Yadav as the new General Manager for South Asia. This strategic appointment is set to mark a significant milestone in the company’s ongoing commitment to excellence and growth in the region.

With a career that has spanned more than 25 years in the poultry industry, Mr. Atmaram Yadav brings a wealth of experience to his new position. Mr. Yadav has been a critical component of AB Vista for the past 14 years, and his leadership and expertise have been instrumental in the company’s success.

With a career that has spanned more than 25 years in the poultry industry, Mr. Atmaram Yadav brings a wealth of experience to his new position. Mr. Yadav has been a critical component of AB Vista for the past 14 years, and his leadership and expertise have been instrumental in the company’s success.

Throughout his time at AB Vista, Mr. Yadav has exhibited exceptional expertise in strategic planning, customer relations, and market development. His innovative approach and profound comprehension of the poultry industry have been critical in the advancement of the company’s market position and the expansion of its footprint. His contributions have not only fortified AB Vista’s industry presence but have also facilitated the development of innovative solutions that cater to changing market requirements.

Mr. Yadav will assume the position of General Manager of South Asia, where he will be responsible for the operational and strategic initiatives of the region. His primary objectives will be to promote innovation, enhance customer engagement, and drive growth. His proven track record and extensive experience render him the ideal candidate to guide AB Vista into a new era of success.

Mr. Atmaram Yadav expressed his gratitude for the opportunity to assume this new position and oversee the South Asia region for AB Vista. “I am eager to collaborate with our esteemed partners and talented team in order to advance our trajectory of innovation and growth.” Together, we will continue to enhance our accomplishments and endeavor to provide our consumers with unparalleled value.

Dieter Suida, the Global Commercial Director of AB Vista, conveyed his confidence in Mr. Yadav’s appointment, stating, “Atmaram’s profound understanding of our business and extensive industry experience render him the ideal candidate for this position.” His leadership will unquestionably enhance our dedication to providing innovative solutions to the poultry industry in South Asia and contribute to our ongoing success.

Under Mr. Yadav’s leadership, AB Vista is poised to further consolidate its position as a market leader in the region, driving forward with renewed energy and a clear vision for the future.

Mr. Atmaram Yadav can be contacted at M: +91-9958299203 or E: Atmaram.Yadav@abvista.com