Whenever a poultry producer faces a problem of lameness, he points his fingers towards feed and the nutritionist.  We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

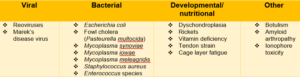

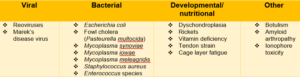

Lameness can have a nutritional, viral, bacterial or traumatic etiology. Asking questions only about feed source, access to feed and changes in feed and its formulation is not sufficient. There can be bacterial and viral infections behind lameness in commercial poultry.

Rule out the infectious factors:

As bacteria (particularly Staphylococcus species) can enter the birds well before the onset of clinical lameness, a full history, including early chick quality, the donor source, scratching injuries, respiratory insults, gut health issues (including the quality of the water) and traumatic tendon damage should be recorded. Chicks source or parent information is important for assessing potential viral etiology and genetic predispositions. Understanding the rapidity of the growth rate and modifications (such as light programs) is important information. It is important to determine the root cause of infection if Staphylococcus aureus or Escherichia coli are involved. They can enter the blood stream through the skin, the respiratory tract, the intestinal tract or during incubation or hatching.

Birds with lameness can often present with varying signs. At least 15 birds with typical clinical signs should be  necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

As lameness due to bacterial infection can often be chronic, antimicrobial treatment will often not resolve the problem. Infection will often be secondary to other causes and the penetration of antimicrobials to the sites of infection is often poor. Label directions for food-producing animal usage must still be taken into consideration. The exception to this will be when Mycoplasma synoviae or Pasteurella multocida are involved. The parent history and other signs in the birds should help differentiate these from other causes, such as Staphylococcus

aureus. Nutritional stress can also trigger bacterial infections. This stress may be due to an inadequate diet, but any factor that inhibits feed intake in some or all birds in the flock can be responsible.

Antimicrobial susceptibility testing should be performed to ensure that the most efficacious antimicrobial is used. A number of antimicrobials, including Amoxicillin, Erythromycin, Tylosin, Oxytetracycline, and Chlortetracycline have been used to treat acute and subacute infections. Clinically affected birds respond well.

Infectious causes behind lameness must be diagnosed. Root cause behind lameness coming from Parents, Hatchery (temperature), Poultry house must be corrected. Use of specific anti-microbial can be a short-term flock specific measure.

Verify Nutritional factors:

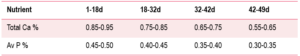

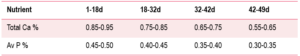

Calcium, Phosphorus and minerals are critical for lameness issues and a good nutritionist always double checks these levels in formulation. Indian nutritionist follows the below levels for broiler formulation.

Optimum Total Calcium to Available P ratio should be between 2.0-2.2 to 1. Though these ratios are not that significant with precise nutrition in current times. The levels in the table are including matrix offered by Phytase suppliers. Calcium concentration may vary by 10% depending upon limestone sources, particle size and solubility. Phosphorus availability is considered 85% from DCP and MBM and 100% from MCP. Average TDS of Indian farm water 1000 and at this level’s calcium concentration is 200mg/L. Birds take 2.5-4 times water against feed in summer. A correction of 5-10% in feed Ca levels needs to be applied considering this.

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption.

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption.

Calcium from Limestone is usually soluble in proximate gut and acts as a bridge in the lower GIT to bind protein. This leads to improper digestion and undigested particles in droppings, a huge issue in summers. Ca has negative interaction with other minerals (P, Mg, Mn and Zn) means if you keep Ca levels higher you need to keep mineral levels high in premix, especially these four. Calcium levels lowers down Phytase efficacy. Excess Ca level in diet increases anti-nutritional effect of Phytate as 1 IP6 can bind with 6 Ca ions. These extra Ca in diet forms insoluble Phytates which is less accessible to Phytase enzyme. Higher level of Ca phytate bindings leads to reduced protein and aa digestibility. Excess Ca in diet depress P digestibility. +0.1% Calcium levels can decrease P digestibility by 4%. When higher Ca levels are used make sure not to take higher matrix of amino acids from Phytase enzymes.

Analyzing at practical Calcium and Available Phosphorus levels in Indian diets, Phytase levels must be included to a minimum of 1000 FYT/kg of feed. Calcium shouldn’t be kept very high fearing lameness as this may have a negative impact on so many performance parameters.

Nutritional causes behind lameness can be due to underfeeding or overfeeding of minerals. Once lameness is seen in the flock, its not a correct way to increase Calcium and Phosphorus levels without analyzing other causes. Mineral sources need to be analyzed for content and availability. Use of Phytase is very critical and it can have a direct role in nutritional cause behind lameness.

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is novellife.bangalore@gmail.com and contact no Landline 080-41326221 Mob- 9611337444).

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption.

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption. (This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

Telangana region. The company engages in the sales of Biologicals, Feed Supplements and Bio Sentry Products for the poultry industry. SV Marketing reaps the benefit of being appointed as the “SUPER DISTRIBUTOR” for the products manufactured by Venkateshwara Hatcheries Pvt. Ltd. in Telangana region.

Telangana region. The company engages in the sales of Biologicals, Feed Supplements and Bio Sentry Products for the poultry industry. SV Marketing reaps the benefit of being appointed as the “SUPER DISTRIBUTOR” for the products manufactured by Venkateshwara Hatcheries Pvt. Ltd. in Telangana region.