Bird-flu scare during the initial weeks of January, 2021 had adverse impact on poultry meat & eggs consumption.  Swift action by the government in collaboration with state governments in dismissing rumours relating to consumption of poultry meat & eggs, helped to an extent in restoring consumer confidence. Concrete measures are needed to ensure that rumours against consumption of poultry meat & eggs circulated at frequent interval are dealt with firmly through sharing of scientific information so that livelihood of millions of farmers and other stakeholders associated with the industry are not hit and poultry industry continues to contribute significantly towards India’s economic growth – Ricky Thaper, Treasurer, Poultry Federation of India.

Swift action by the government in collaboration with state governments in dismissing rumours relating to consumption of poultry meat & eggs, helped to an extent in restoring consumer confidence. Concrete measures are needed to ensure that rumours against consumption of poultry meat & eggs circulated at frequent interval are dealt with firmly through sharing of scientific information so that livelihood of millions of farmers and other stakeholders associated with the industry are not hit and poultry industry continues to contribute significantly towards India’s economic growth – Ricky Thaper, Treasurer, Poultry Federation of India.

India has been reporting a few cases of Avian Influenza (AI) commonly known as ‘bird flu’ since 2006. In the first week of January, 2021, the Ministry of Animal Husbandry, Dairying and Fisheries had stated that ‘bird flu’ cases have been reported mostly in bird populations such as crow, migratory birds, ducks and goose birds.

While reports of ‘bird flu’ not only impacted poultry meat & eggs industry in terms reduction in consumption, it also adversely hit other stakeholders like farmers growing maize and soya (used as poultry feed ingredients) as prices of these commodities declined because of lack of meat demand. Keeping in mind its impact on the poultry business, Ministry of Animal Husbandry, Dairying and Fisheries, Government of India took prompt actions and urged state governments to raise awareness amongst the consumers of poultry meat & eggs that its safe for consumption so that people are influenced by mostly fake news or rumours.

“The AI is a virus that can infect birds. India has been reporting the disease since 2006 and till date there is no report of human infection. The country had controlled the disease effectively through culling. There is no scientific report available all over the globe that the infection of H5N1 or any other strain of Avian Influenza viruses spread through the processed products,” Dr. OP Chaudhary, Joint Secretary, Ministry of Animal Husbandry, Dairying and Fisheries, GOI, stated in his letter to all Principal Secretaries, Animal Husbandry from States and other officials. These are most welcome steps.

In a bid to convey the message about safety of poultry meat & eggs consumption, Animal Husbandry and Dairying Minister Shree Giriraj Singh Ji organized press conferences and made the statement that there have been no scientific reports on transmission of bird flu to humans and consumers should not be scared. This confidence building communications by Honorable Minister, Shree Giriraj Singh Ji was very much appreciated by the entire poultry industry.

The Ministry of Animal Husbandry and Dairying requested state administration to issue instructions to concern State authorities and local administration against imposing a ban and allow selling of poultry products sources from one state to other state. However, the government in collaboration with industry must ensure that unfounded rumours as well as fake news against consumption of poultry meat & eggs is countered periodically with scientific studies. Even if bird flu incidents are not reported amongst poultry birds, its impacts consumption of meat & eggs because of unfounded or fake news circulated in the media. Millions of people are engaged in the poultry value chain and such news impacts livelihood as well as impacts overall economic growth of the country as poultry sector contributes significantly to the contribute India’s GDP.

The World Health Organization also states that it is safe to consume poultry meat and eggs. According to the WHO website, there is no epidemiological data which suggests that the disease can be transmitted to humans through cooked food. The virus is destroyed at 70°C if held for about 3 seconds. Also, properly cooking meat or eggs to achieve a temperature of 74°C in eggs or all parts of meat will inactivate the virus. FSSAI urges the FBOs and consumers not to panic and ensure proper handling and cooking of poultry meat and eggs for its safe consumption.

In a welcome step, the Food Safety and Standards Authority of India (FSSAI) had issued a guidance document (on January 21, 2021) on “Safe handling, processing and consumption of poultry meat and eggs during bird flu Pandemic” for creating awareness amongst Food Business Operators and consumers. Such communications create confidence amongst the consumers of poultry meat and prevent unnecessary panic created on the basis of false information about the poultry industry.

In India, the disease spreads mainly by migratory birds coming into India during winter months. However, it’s the poultry industry which is adversely impacted as consumers reduce consumption of poultry meat & eggs notwithstanding that there are several studies which state that meat & eggs consumption is safe. Poultry industry, which is witnessing a healthy growth rate especially in the last two decades, faces a slump in the demand for meat & eggs because of false information being spread during the bird flu outbreak, which virtually disrupts the value chain adversely impacting the industry.

Thus, all the stakeholders in the value chain from poultry farmer owners to sellers along with the government agencies must ensure continuous awareness creation about the safety protocols being followed by the industry to dispel any doubts in the minds of consumers. This would prevent frequent volatility in the demand for meat & eggs because of few reports about bird flu and shall save livelihood of farmers as well as other stakeholders in the value chain.

Digesting feed and absorbing nutrients

Digesting feed and absorbing nutrients

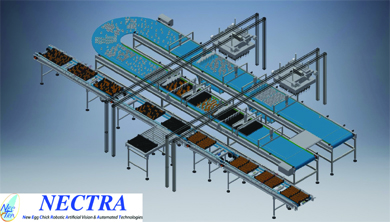

Agrivida, a privately held biotechnology company based in Massachusetts, was founded in 2003 by scientists from MIT who discovered a way to incorporate feed additives directly into corn grown for production animals. By having the additive inside of the grain, the molecules are more efficiently absorbed, and producers can improve both animal performance and their bottom line.

Agrivida, a privately held biotechnology company based in Massachusetts, was founded in 2003 by scientists from MIT who discovered a way to incorporate feed additives directly into corn grown for production animals. By having the additive inside of the grain, the molecules are more efficiently absorbed, and producers can improve both animal performance and their bottom line.