This article talks about how you could strengthen recruitment and selection process by making strategic decisions. Importance of internal talents and employee retention is focused upon. Also, this article provides few steps in making your hiring process effective and reduce hiring errors. The importance of coordinated efforts from all functions too is highlighted.

One of the things this pandemic has highlighted is the need for a well trained and engaged employees. Several CEO surveys have concluded that getting right talent happens to be one of the top challenges for the CEOs. Our animal nutrition industry is no different as we are witnessing instances where teams have delivered while some others have not been so successful. What makes hiring difficult? Why some organizations are successful in attracting/retaining talents while several others struggle. We will examine these issues in this article.

surveys have concluded that getting right talent happens to be one of the top challenges for the CEOs. Our animal nutrition industry is no different as we are witnessing instances where teams have delivered while some others have not been so successful. What makes hiring difficult? Why some organizations are successful in attracting/retaining talents while several others struggle. We will examine these issues in this article.

To me there are two fundamental issues in how we hire today. They are:

- More focus on external hiring for any open positions

- Inability to retain talents

Let us study them in detail here. On the first issue of dependence on external hiring, studies suggest that the percentage of positions filled with internal candidates has gradually declined over the past decades to below 15% now. Advantage with an internal candidate is that they need very little time to settle down and perform in the new role compared to an external candidate for the same roll where it takes about 1-2 years for them to deliver. When the organization predominantly looks to fill open positions with external hires, there is very little incentive for existing employees to stay back and grow. They start spending significant amount of time searching for opportunities outside the organization. Moreover, filling a position with internal candidate is very quick when compared to an external hire. I am not suggesting that all positions need to be closed with internal candidates. Please have a systems in place to provide opportunity to our existing employees before we start looking at the market. Internal movement also causes a cascading effect as we will need to fill the position vacated by the internal candidate. This creates lot of opportunities and helps an organization in managing employee aspirations.

On the second issue of inability to retain talent, let me state that studies suggest that about 95% of the positions that are closed today are replacement positions. This is a clear evidence of our inability to retain talents and key employees. Also, studies find out that more than two thirds of these employees who leave say that they left because of better career prospects. Question is why the current organization can’t provide that opportunity to these employees instead of making them leave. Problem with refilling an open position is that it takes lot of time and resources. On an average every position takes about 45-90 days for a closure. If this was a sales position, it causes direct revenue loss. Worst, that business is bagged by a competitor and we need to spend three times the resources to get back that business. Apart from time and resources, frequent re filling also causes a bad reputation in the market as more people come to know that same or similar positions are always open with the organization. Not to mention the fact that in several cases organizations end up paying more for the recruit compared to the person whom he/she replaced.

We come the question of what we could do to address these issues so that we could be very successful in the market. Based on my experience, I am suggesting the below measures.

- Internal Hires – For any open position (replacement or new) you may consider internal candidates first. You need to make them aware of these opportunities by way of internal job postings. Smaller organizations might have challenges in providing faster growth in the same function where growth across function comes handy. One way to make employees think about this is encouraging eligible candidates to apply for open positions within the organization. If you don’t provide an opportunity to grow, someone else is going to do that. While you post these jobs internally, train managers to allow their employees apply to them without any fear of retribution. Be open to evaluate the internal applications in a very transparent and objective manner. Key here is to communicate your decision of either offering or not to the candidates in a timely, open and constructive manner. Failure to do so could be counterproductive and might result in these employees leaving the organization with bitterness. Believe me, I have seen employees move from core R&D role to a sales role and excel.

- Write realistic Job descriptions – It is always good to have an ideal candidate, but I only wish if there were any. For instance, we were looking for Product managers who had a Veterinary degree with an MBA and domain experience. No wonder we always struggled to find candidates. Slowly we had spoken to almost all of them who were working with our competition. Then we started to look for candidates with core Product management experience in a similar industry who were not vets. The basic technical training was imparted. It worked wonders and I can safely say that there is no evidence to say that Vet degree offers an advantage for this product manager position. I am in no way dis crediting vet graduates here. Problem is with very limited veterinary universities; the talent is limited, and we had to compete with governments who are their biggest employer. Be clear on what you consider as essential and what is good to have.

While writing a JD for a position, managers need to take stock of the skills that are available in their function and decide which skill is needed. For instance, the head of R&D (during my last corporate stint) was smart enough to build a team of scientists with varied specializations like biochemistry, microbiology, molecular biology, organic chemistry etc. Over a period of 2 years, he was successful in building a strong team that had the expertise to take on projects on wide variety of subjects and species. Today, this R&D function tops in terms of innovation, paper publications and is a source for talents for other business units.

Managers/Functional heads need to have such a long-term thinking while hiring.

- Invest in your employees and Fresh talent – Your existing employees need to be nurtured so that they grow and occupy key positions. One of the myths in people development is to send them for training programs and count the man-days. Reality is it takes more than just man-days to help them grow. They need right working environment where they enjoy freedom and empowerment, they should be encouraged to take calculated risks (Please refer my earlier article on this subject). Those with high potential need to be exposed to more than one function, be part of cross functional teams and in select cases coaches assigned to them.

Investing on freshers pays dividends in long run as they could be trained in your way of functioning. Even before you decide to hire freshers, you may need to identify projects for them and have a structured training. They should be assigned to a mentor who shapes them. In my experience I have hired freshers in my HR function who have grown to occupy managerial positions in a span of 4-5 years.

- Recruit all through the year and select when you have a position – Make the distinction between recruitment and selection. Recruitment refers to the process of identifying potential candidates for current and future positions while selection happens when there is an open position. All Managers need to constantly look for potential candidates (internal and external) regardless of whether they have an open position or not. For instance, a sales manager could easily identify potential frontline sales personnel by looking at who is giving a tough competition or who is grabbing our share? Visits to distributors could be used to identifying potential candidates. You need not approach them for any position but need to keep a tab

- Do a thorough reference check – This step is largely under-utilized and could help you in avoiding hiring errors. Ideally reference check is done by the hiring manager with a person who had managed the candidate. Quality of information you gather largely depends on the quality of questions you ask. It is better to explain the job in detail to the person providing reference and seek information on how the candidate has performed in similar role earlier, how has he/she responded to deadlines, what has been the accomplishments, what could he/she have done better, why did he/she leave the organization and what need to be ensured to make the candidate successful. Please reach out to them to fix up a 15–20-minute time slot and be prepared for the discussion. Use this information to write a solid induction program for the recruit

- Measure – It is said that what you don’t measure, you can’t control. Often, we complain about delay in hiring or lament on the need to go for frequent replacements. Seldom do we measure, track and draw insights into the root causes. Things like time to fill, time to source, number of resumes per closure could provide valuable insights. When I was managing HR function, we found that consultants had given more than 600 resumes for less than 15 closures while 65 odd employee referrals resulted in about 30 hires. Tracking employee retention by source of hiring will help you fix issues in recruitment. For example, we found internal candidates had highest retention while the candidates hired through consultants had highest attrition within 6 months of joining.

Conclusion– As we have seen, recruitment requires a well-coordinated effort and must be data driven. Like any process, it too needs constant monitoring and correction. Recruitment needs to have a strategic approach by all functions and not just the HR function. Jack Welch says, “If you pick the right people and give them the opportunity to spread their wings and put compensation as a carrier behind it, you almost don’t need to manage them”. So True

About the Author: Mr. Pattabiraman Nagarajan is a HR professional, Consultant, trainer and an ICF certified coach. Has managed organization change and aligned HR practices to ensure business growth. He holds master degree in Social work and a PG diploma in Business management from IIM Trichy. He could be reached at npattabiraman@relyonus.in

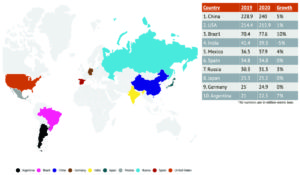

The survey showed that, regionally, COVID-19 had varying effects. Some regions, such as Africa, cited more challenges than others, and in many cases, this was a country-by-country determination. The rise of e-commerce was seen around the world and is expected to be ongoing for food purchasing in the future.

The survey showed that, regionally, COVID-19 had varying effects. Some regions, such as Africa, cited more challenges than others, and in many cases, this was a country-by-country determination. The rise of e-commerce was seen around the world and is expected to be ongoing for food purchasing in the future.

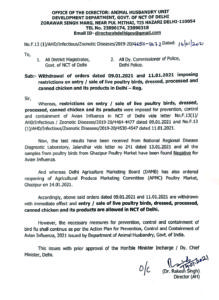

Poultry meat and eggs are generally considered universal foods. Some industry challenges arose from the widespread shutting down of restaurants. Disease, such as avian influenza, was also a concern and remained a challenge for many in the business. However, offsetting any declines in feed production due to these challenges was an increased interest in eggs as an inexpensive protein, particularly for those in economically suppressed areas.

Poultry meat and eggs are generally considered universal foods. Some industry challenges arose from the widespread shutting down of restaurants. Disease, such as avian influenza, was also a concern and remained a challenge for many in the business. However, offsetting any declines in feed production due to these challenges was an increased interest in eggs as an inexpensive protein, particularly for those in economically suppressed areas.

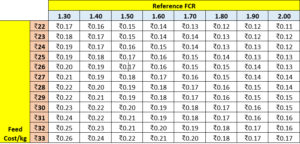

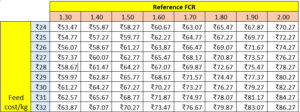

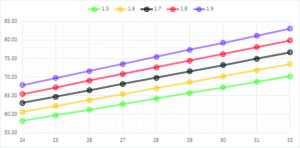

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost)

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost)