Without relying on artificial fortification, biofortification is a natural method of delivering nutrients from natural sources and has the potential to be beneficial through base laying hen feed. It is also the most successful recent method of delivering micronutrients and addressing nutrient deficiencies. The main motto of such method is to produce eggs that are high in linolenic acid, a precursor to DHA (docosahexaenoic acid), a substance that may also offer protection from the devastating ischemic heart disease. The egg can also be supplemented with organic selenium, vitamin K, and omega 3 fatty acids. Eggs with a dark orange yolk and low cholesterol can be produced via biofortification.

Former Associate Professor & H.O.D.

Dept. of Zoology

R.K.Mission V.C.College

Kolkata 700118,W.Bengal, India.

Senior Consultant-Poultry, Vet & Aqua inputs

In West Bengal

Medivin Pharmaceuticals,

Hyderabad 500070.Telengana.

Eggs are a necessary component of human diet since antiquity. No other animal-derived food is consumed by as many people worldwide, and none is prepared in as many distinct ways. According to a 2023 report, the average Japanese citizen consumes 320 eggs per year. In India, however, per capita egg availability was only 86 eggs per year (2019-2020). Food is today created not only to satisfy hunger and to provide important nutrients for individuals, but also to prevent nutrition-related diseases and promote consumers’ physical and mental well-being.

Furthermore, there has been an increase in demand for functional foods (foods that have a potentially positive effect on health beyond basic nutrition) in recent decades, which is expected to continue in the future due to their ability to reduce the risks of some diseases as well as increase life expectancy. The contents of a chicken egg can be modified to make it more nutritious and appealing to a part of our consumers who are willing to pay extra for those modifications in the egg.

In Search of Functional Eggs

Scientists are investigating the possibilities of developing “functional eggs” or “designer eggs” or “fortified eggs” using technological means in light of the prospective market for these eggs. Dark orange yolk eggs may be particularly appealing for the inclusion of bioactive substances. Furthermore, these products are safer from a microbiological standpoint, less expensive, and easier to handle and store. As a result, functional egg-derived products generated through technological approaches may be a very alluring choice for growers as well as customers.

Versatility of Egg as Food

Eggs are a low-cost, high-nutritional-value food that contains 18 vitamins, minerals, and other vital components. Some of these minerals, such as zinc, selenium, retinol, and tocopherols, are low in Western diets [1]. Cryptoxanthin is a natural carotenoid pigment found in eggs that has antioxidant properties and may protect people against a variety of degenerative diseases, including CVD. Other biologically active chemicals found in eggs may play a role in the treatment and prevention of chronic and infectious disorders.

Eggs have been found to have antibacterial, immunomodulator, antioxidant, anti-cancer, and anti-hypertensive substances. Egg albumen contains biologically active proteins such as lysozyme, ovomucoid, ovoinhibitor, and cystatin. Eggs are high in lecithin, a polyunsaturated phosphatidylcholine. It stimulates bile secretion, reducing bladder stagnation and, as a result, decreasing lithogenicity. Eggs have a modest caloric content (about 150 kcal/100 g), a high protein content, and are a gourmet treat.

Designing Functional Egg

A functional egg is one that has more nutrients or a different chemical makeup than regular eggs. These nutrients are typically bioactive substances that protect or prevent diseases. The total nutritional makeup of eggs is critical for functional egg. Functional eggs outperform regular eggs in terms of physical attributes.

There are several methods for producing functional eggs, including triggering metabolic changes in the hen, changing membrane transport characteristics, and manipulating diet. Cholesterol level, fatty acid profile (omega-3 and omegra-6), vitamins (E, D), folic acid, minerals (Fe, Zn, Se, I, and Cr), carotenoids, lutein, and yolk colour can all be altered.

Eggs are of particular relevance from a functional standpoint since they provide a moderate calorie source (approximately 150 kcal/100 g), an excellent quality protein, significant culinary flexibility and a low economic cost, making eggs affordable to the majority of the population. Eggs are also relatively high in fat-soluble substances, making them a beneficial addition to the diet of people of all ages and stages of life. Eggs, in particular, may be very beneficial in the diets of people at risk of low nutritional consumption, such as the elderly, pregnant women, and children. Furthermore, it should be noted that eggs are consumed all throughout the world, with no religious limitations.

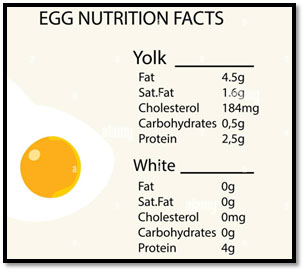

Eggs & Cholesterol

According to nutritional experts and health agencies, eggs are a contentious food because of the saturated fat content (approximately 3 g/100 g) and cholesterol content (around 200-300 mg/100 g). This fact suggests that a high dietary cholesterol intake is linked to high blood cholesterol levels and CVD. Experts currently recommend consuming as little dietary cholesterol as possible, aiming for less than 300 milligrams (mg) per day. If you don’t eat many other cholesterol-containing foods, it may be fine to eat more eggs. Recent research suggests that the link between eating eggs and elevated heart disease risk may not be as strong as once thought — though there is still much debate on the topic.

Omega-3-Fortified Eggs

Commercial table eggs are abundant in n-6 PUFA but low in n-3 fatty acids. It has been discovered that attempts to generate eggs high in n-3 PUFA, key family of polyunsaturated fats are successful. Increase in n-3 PUFA in egg could be very beneficial. The most straightforward method is to generate an egg rich in linolenic acid, which is a precursor of DHA (docosahexaenoic acid) and is also thought to protect against deadly ischemic heart disease. For this goal, the hen’s diet is fed frequently high in flaxseeds, linseeds, or their corresponding oils.

Vitamin K Fortified Eggs

It has been documented that over half of all adults in Ireland, the United Kingdom (UK), and the United States of America (USA) have poor vitamin K intakes. Biofortification of vitamin K resulted in significant increases in the yellowness of egg yolk. At a dose of 25 mg/kg administered through hen feed, vitamin K3, in the form of MNB (Menadione Nicotinamide Bisulfite), was shown to double the vitamin K content of the egg. Biofortification of eggs with vitamins is one of the most promising ways for increasing vitamin consumption in the population.

Organic Selenium Fortified Egg

Although Se’s potential as an antioxidant for the prevention of cardiovascular diseases (CVD) appears promising but more long-term intervention trials are required. Some intriguing studies linked Se consumption to a lower prevalence and risk of prostate and colon cancer. According to new research, including organic selenium in chicken feed (0.3-0.5 mg/kg) can dramatically increase the content of this trace element in eggs. As a result, Se-fortified chicken eggs are possible [2].

Low Cholesterol Eggs

large egg usually contains 200 – 220 mg of cholesterol. Lowering egg cholesterol levels can be accomplished through dietary changes or pharmacological intervention (drugs). Drugs reduce cholesterol in eggs by either blocking cholesterol synthesis in the hen or inhibiting cholesterol transfer from the blood to the developing yolk on the ovary. At the moment, the FDA has not authorised any of the medications that have showed promise in decreasing cholesterol in egg for commercial usage.

Supplementing chromium to laying hen diets at concentrations less than 1 ppm has been demonstrated to minimize egg cholesterol while also improving egg interior quality. Feed components containing active compounds like as isoflavones have the potential to significantly reduce egg cholesterol levels. Soybeans and soybean products contain high levels of isoflavones.

Biofortified Dark Orange Yolk Eggs

The colour of the yolk is an important egg quality trait for the egg industry and customer choice. Consumers in most nations prefer coloured egg yolks with golden-orange tones. The pigments in the chicken’s food cause the hue diversity in egg yolks, which ranges from dark orange to virtually white. Some producers employ particular feed additives containing both yellow and red carotenoids from natural and artificial sources to achieve a darker coloured yolk. Carotenoid content of Orange Corn is high & when given in poultry diets carotenoid level in egg yolk increases [3]. The bioavailability of lutein also can be significantly boosted in chicken egg. Higher levels of lutein, a carotenoid, has been linked to a lower risk of a variety of health issues, including age-related maculopathy, cardiovascular disease, Alzheimer’s disease, and certain types of cancer.

Conclusion: Egg is a nutritious food that is inexpensive and can be supplemented with various nutrition via feeding techniques. Designing eggs with health-promoting nutrients would be an intriguing idea. Designer or fortified eggs are not only healthy and delectable, but they also boost consumers’ overall health. Designer eggs necessitate the use of appropriate technology and expertise. Because the cost of manufacturing will be more than the cost of typical table eggs, the producers should conduct market research before venturing the business decisions.

References: 1. World Health Organization, Food and Agriculture Organization of the United Nations. Vitamin and Mineral Requirements in Human Nutrition external link disclaimer. 2004. 2. Navarro-Alarcon M, Cabrera-Vique C. (2008) Selenium in food and the human body: a review. Sci Total Environ.Aug 1;400(1-3):115-41. doi:10.1016/j.scitotenv.2008.06.024. Epub 2008 Jul 26. PMID: 18657851. 3. Elizabeth Doughman (2023) Orange corn could make eggs more nutritious. April 5.WattPoultry.com.

Eggs are a controversial food because of the saturated fat content (approximately 3 g/100 g) and cholesterol content (around 200-300 mg/100 g). An egg white contains fewer calories than a whole egg. It is also lower in protein, cholesterol, fat, vitamins, and minerals.

The American Egg Board asserts that yolk colour has no bearing on egg quality, flavour, nutritional content, cooking properties, or shell thickness. Eggs of different colours may have somewhat different micronutrient concentrations of vitamins A and lutein, but their macronutrient compositions are the same. In the end, an egg is an egg.

For more details, contact the author at parthapbis2006@yahoo.co.in

Image Source: Author

Impressive Engagement at the Event: During the Livestock Philippines 2023 event, Biochem Pharma actively engaged with industry leaders, experts, and stakeholders. The company participated in insightful discussions and knowledge-sharing sessions, contributing to shaping the future of animal health. Their presence and commitment to excellence drew attention and admiration from attendees, cementing Biochem Pharma’s position as a trusted leader in the field.

Impressive Engagement at the Event: During the Livestock Philippines 2023 event, Biochem Pharma actively engaged with industry leaders, experts, and stakeholders. The company participated in insightful discussions and knowledge-sharing sessions, contributing to shaping the future of animal health. Their presence and commitment to excellence drew attention and admiration from attendees, cementing Biochem Pharma’s position as a trusted leader in the field. innovation and make significant contributions to the animal health industry. As a trusted leader, the company remains steadfast in its mission to enhance animal well-being, improve productivity, and support the sustainable growth of the livestock sector. With their progressive approach and commitment to excellence, Biochem Pharma is poised to shape the future of animal health.

innovation and make significant contributions to the animal health industry. As a trusted leader, the company remains steadfast in its mission to enhance animal well-being, improve productivity, and support the sustainable growth of the livestock sector. With their progressive approach and commitment to excellence, Biochem Pharma is poised to shape the future of animal health.

The technical session about the topic “Resource Management Strategies during Tough Times” was presented by the keynote speaker Dr Uday Patel. He discussed about the strategies to overcome current, future raw material challenges, its impact on cost of production and on overall balance sheet of businesses. He explained the audience about importance of gut health & strategies to overcome that, another major topic was how Indian producers can improve quality of meat to increase the consumption. He discussed all the topics in depth and shared his experiences with help of relevant technical data. All the participants appreciated the knowledge shared by the speaker.

The technical session about the topic “Resource Management Strategies during Tough Times” was presented by the keynote speaker Dr Uday Patel. He discussed about the strategies to overcome current, future raw material challenges, its impact on cost of production and on overall balance sheet of businesses. He explained the audience about importance of gut health & strategies to overcome that, another major topic was how Indian producers can improve quality of meat to increase the consumption. He discussed all the topics in depth and shared his experiences with help of relevant technical data. All the participants appreciated the knowledge shared by the speaker.

In one of the panel discussions on ‘Animal Health for One Health Management’, Dr Arun Atrey, MD & CEO, Zenex Animal Health joined as panelist. Other panelist in session were Dr Praveen Malik, CEO, Agriinnovate, Mr Stanely Fenwick, Technical Lead for One Health, Mott Macdonald, Dr A Sahoo, Director, NRC Camel, ICAR and Dr Avinash Anand, CEO &MD, Sheep & wool Dev Board. The session addressed various initiatives of Govt., industry and other organizations for creating awareness and implementation of One Health.

In one of the panel discussions on ‘Animal Health for One Health Management’, Dr Arun Atrey, MD & CEO, Zenex Animal Health joined as panelist. Other panelist in session were Dr Praveen Malik, CEO, Agriinnovate, Mr Stanely Fenwick, Technical Lead for One Health, Mott Macdonald, Dr A Sahoo, Director, NRC Camel, ICAR and Dr Avinash Anand, CEO &MD, Sheep & wool Dev Board. The session addressed various initiatives of Govt., industry and other organizations for creating awareness and implementation of One Health.

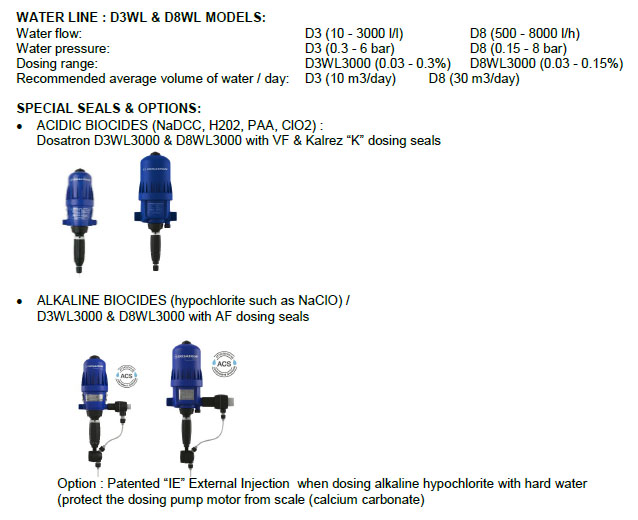

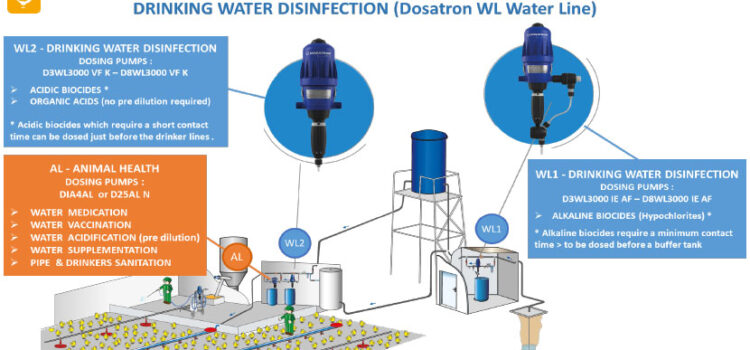

Ability to operate at the lowest water flows

Ability to operate at the lowest water flows Very low dosing capability with a minimum dosage at 0.03%

Very low dosing capability with a minimum dosage at 0.03%