An Exclusive Interview with Poultry TRENDS magazine, Prof. Aniruddha B. Pandit shares his Innovative Technology for converting keratin waste (poultry feathers, human hair and wool) to animal feed, fertilizer and protein supplements.

Prof. Aniruddha B. Pandit is the Vice-Chancellor of the Institute of Chemical Technology, Mumbai, (India) and the  principal investigator of developed novel keratin valorization technology. His research group at the Department of Chemical Engineering, Institute of Chemical Technology, Mumbai, is the pioneer in advanced oxidation processes such as hydrodynamic cavitation technology and its applications in various areas such as water treatment, process intensifications in physical, chemical, biological processes, and extraction of biomolecules from microorganisms.

principal investigator of developed novel keratin valorization technology. His research group at the Department of Chemical Engineering, Institute of Chemical Technology, Mumbai, is the pioneer in advanced oxidation processes such as hydrodynamic cavitation technology and its applications in various areas such as water treatment, process intensifications in physical, chemical, biological processes, and extraction of biomolecules from microorganisms.

Under the supervision of Prof. Aniruddha B. Pandit, one Research group (Dr. Sachin B. Jadhav, Dr. Vaibhav R. Acham and Dr. Muntazim Munir Khan) has worked on the valorization of chicken feather, which is being commercialized at large scale in industrial collaboration.

The other Research Group (Mr. Jayesh Mevada and Mr. Ketan Desai), has worked on human hair and wool.

What is Keratin, and where does it come from?

Keratin is a highly specialized fibrous structural protein synthesized inside the epithelial cells of humans and higher vertebrates. The high cysteine amino acid content is the main characteristic that differentiates Keratin from the other structural proteins such as collagen and elastin. Cystine residues of neighbouring polypeptide chains are covalently linked together through disulfide bridges. This results in a high degree of cross-linking that brings about the formation of a tight and compact structure. The amount of the keratin protein contents varies from 70 % to 85 % as per the source of Keratin, such as human hair, poultry feathers, horns, bristles, and wool, etc.

How much is keratin waste globally and in India?

Keratin wastes are considered environmental pollutants and are mostly generated from poultry farms, slaughterhouses, and leather industries. The main producer of keratin waste includes the United States of America, China, India, and Brazil, producing millions of tons of keratin waste.

Worldwide, around 2 million metric tons of wool, 0.3 million tonnes of human hair, and 8.5 billion tons of poultry feathers are generated annually, of which India contributes to 350 million tons. India generates a huge amount of human hair, animal hair, poultry feather waste, and wood waste each year. These keratin wastes are the third most abundant renewable polymeric material present in nature after cellulose and an inexpensive source of amino acid and Protein – underlining their potential to be used as animal feed and fertilizer.

What are the ill effects of keratin waste?

Animal hair, poultry feathers, and other keratin-containing waste are usually dumped, sometimes landfilled, and incinerated. This is observed throughout the world. But such action leads to pollution of soil, water, and air. These wastes increase environmental hazards and pollution and threaten public health while also increasing greenhouse gas emissions. Keratin-rich wastes such as feathers also cause many diseases in humans.

Please explain your Innovative Technology

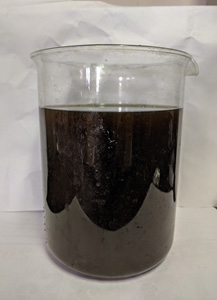

The research group lead by Professor Pandit at the Institute of Chemical Technology, Mumbai, India, has developed a technology to covert the keratin waste to food for pets and fertilizers for plants with support from the ‘Waste Management Technology’ program of the Department of Science and Technology, Government of India. The research group is specialized, and a pioneer in hydrodynamic cavitation technology and have successfully commercialized for process intensification in chemical, physical and biological processes for water treatment and waste management. The research group used an advanced oxidation method for the conversion of the waste to commercial fertilizers and animal feed. The technology involves pre-treatment followed by the hydrolysis of Keratin using a technique called hydrodynamic cavitation, which involves vaporization, bubble generation, and bubble implosion in a flowing liquid. The developed novel technology is patented, easily scalable, environment-friendly, energy-efficient, and will make amino acid-rich liquid fertilizers and feeds more economical than currently marketed products.

The current chemicals and the physical methods for such conversion are energy-intensive, chemically hazardous, and involve multiple steps – resulting in a higher cost of the final product. The developed technology is semi-continuous, with less unit operation and process time required as compared to the conventional chemical, physical and biological processes. The cost of the product at a large-scale plant is up to three folds cheaper than the existing market product. The technology is successfully developed on a pilot scale for various keratin-rich wastes such as human hair, wool, and chicken feathers to highly valuable products such as protein and amino acid hydrolysate, liquid fertilizer, and animal feeds. The demonstration plant for keratin processing is shown in Figure 1.

The total time and steps required for the process depend on the type of end product needed.

- If the end product is animal feeds or fertilizers, it takes about six to eight hours.

- If the target end product is to isolate the specific Protein out of it, then additional steps are involved for protein extraction.

- If the target end product separates the amino acids from the Protein, then further specific steps must be followed.

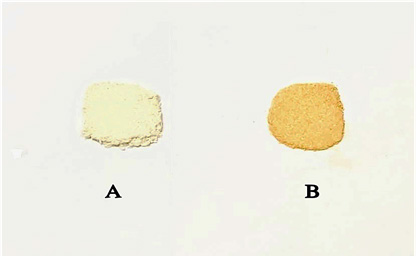

Scientists have also successfully isolated the Protein from wool, chicken feathers, and human hair, which can be additionally used for animal feeds and cosmetic applications [Figure 2].

The isolated Protein from chicken feathers [a], human hair [b] is shown in Figure 3.

These proteins having applications as animal feeds, cosmetic formulations, protein supplements, etc

What is the process of converting poultry feathers into animal feeds and liquid fertilizer?

The overall process for converting the poultry feathers involved washing and cleaning of poultry feathers followed by the hydrolysis and extraction of the Protein using advanced oxidation. The hydrolysate can be further used as liquid fertilizer with other additive nutrients, and also it can further be used for the isolation of Protein and amino acids. The final proteins and amino acids are having high quality, and they can be an affordable source of Protein and amino acids as animal feeds.

Benefits/ Impact of this Technology

When every possible move is being made to attain developments sustainably, the new technology is a positive development in addressing environmental concerns while also providing scope for aquatic and poultry feed.

-

The Developed Technology is easily scalable and sustainable to convert keratin waste in high value addition products such as liquid fertilizer, animal feeds, protein supplements, and cosmetic formulations at an affordable rate.

-

Animal feeds supplement to poultry farmers at an affordable rate

-

Additional Revenue generation for poultry farmers from waste.

- Sustainable technological solution for addressing environmental concerns.

What is the economics involved?

This technology will make the liquid biofertilizers more efficient than the marketed product. The developed liquid fertilizer product is extremely economical. Even liquid fertilizer will be sold for Rs. 0.20 to 0.30 USD per litre. The nitrogenous fertilizers are easily digestible by plants and promote plant growth. This innovation in natural fertilizer is essential as the world is trying to move away from synthetic products due to their numerous hazards.

The developed technology is sustainable and environmentally friendly and produces no such chemical waste at the end of processing, fulfilling the demands of a sustainable and clean process to protect the environment. The cost of isolating Protein in pure form – that can be used as a protein supplement for human consumption – is calculated out to about Rs. 2 $ per kg,” said Professor Pandit. “Compare that to the price of protein supplement currently available in the Indian market for around Rs. 9 to 10 $ per kg.

How can Poultry Farmer benefit?

The advancement in technology production will make the Protein, which is three folds more efficient than the marketed product, available to farmers at an affordable rate. This technology also resolved the poultry farmer’s waste disposal issue and generated extra revenue from the keratin waste. Thus, it can help in the socio-economic development of the farmers and the country.

The scientists suggest the collection of the chicken feather waste and processing them onsite is optimal as it makes them easier for transportation and solves the issue of untreated chicken feathers present several health hazards.

The concept of a mobile collection unit can collect the keratin-rich waste and pre-processing it at poultry houses to avoid the spread of human health hazards and transportation issues. The mobile collection unit can be installed so that poultry farmers can pre-process raw materials, which can be sent to the industry for further processing. This solution provides benefits to the poultry farmers to generate the a- revenue from the chicken feathers waste and resolved the issue of waste disposal. The developed final product can be a cheap source of protein supplement, which can be used as a protein supplement with other animal feeds at a low cost.

How big a Setup is required for converting keratin waste into animal feeds and fertilizers?

Currently, the technology is under commercialization with a capacity of 1 tonne per day of keratin waste processing into animal feeds, liquid fertilizer, amino acid, and protein supplements.

What other areas can this technology be useful in?

The developed technology is successfully tried for the effective extraction of an essential compounds from other natural sources. We are commercializing the technology for the valorization of agriculture waste into valuable products and exploring the application for further waste valorization also, the scientists said.

Is this process environment friendly?

The developed technology is environmentally friendly and does not generate any waste in the process, which is harmful to the environment. It addresses waste management and environmental pollution issues and generates extra income for poultry processing plants.

It seems to be good solution for processing plant where lot of feathers remains as waste

I would like to start a small scale industry on keratin extraction,

Can it be viable?

Please connect with Prof. Pandit at dr.pandit@gmail.com/ Mr. Desai at desaiketan90@gmail.com

Hello Dr. Pandit,

Currently my husband and I started a farm of chicken and duck in the Philipppines. I am aware that the internal organs and feather waste would contribute hazzard to the environment and I am looking for a solution. I searched and found your website. I read your published solution for feathers.It is promising a very good solution not just eliminating pollutants but can generate more income if learn how to process it. I would like to know how can I buy your machine/technology and how much would it be?

Thank you and have a wonderful day.

Sincerely,

Perlita Ambrocio