The Role of Marginal cost and consumer surplus theory on the economics of Broiler Chicken Production

Synopsis: There has been series of discussions in the area of profit maximisation through input cost optimization. However very less discussion has been brought in the area of when and how much to produce. The theory of when and how much to produce relates to the basic theory of marginal cost, consumer surplus and law of diminishing returns. In this article, an attempt has been made to bring in these concepts in relation to production decision and also the efficiencies measurement from the perspective of the resource allocation. The resource allocation can be across the sectors in the broiler production cycle in a vertical tree or in the horizontal and peripheral domain area. In the near future, the implementation of Artificial intelligence (AI) & machine learning (ML) and digitalization of the production value chain would further play a significant role in identifying the key factors associated with cost and revenue in the broiler production cycle and their moderation in the context of consumer demand and supply.

Background :  Over the years, Indian Poultry sector has metamorphosized as one of the most promising sector within the agribusiness spectrum contributing to ~ 5% of the agricultural GDP of India. In recent years, the broiler production and farming has emerged as attractive farming activities due to the higher Return on Investment (ROI) against the land area utilization. There has been a significant improvisation in feed conversion ratio (FCR) and other related production parameters in last one decade as a result of upgradation in genetic traits, superior feed formulations, and scientific management practices. In recent times, the farmers and the integrated broiler chicken producing organizations could achieve remarkable production performance by optimizing the cost driving factors such as FCR, average body weight, liveability and meat yield.

Over the years, Indian Poultry sector has metamorphosized as one of the most promising sector within the agribusiness spectrum contributing to ~ 5% of the agricultural GDP of India. In recent years, the broiler production and farming has emerged as attractive farming activities due to the higher Return on Investment (ROI) against the land area utilization. There has been a significant improvisation in feed conversion ratio (FCR) and other related production parameters in last one decade as a result of upgradation in genetic traits, superior feed formulations, and scientific management practices. In recent times, the farmers and the integrated broiler chicken producing organizations could achieve remarkable production performance by optimizing the cost driving factors such as FCR, average body weight, liveability and meat yield.

In this article, at attempt has been to highlight the decision dynamics on various cost driving factors and their subsequent implications on the economy of broiler chicken production.

There are three fundamental areas that determine the cost economy and profitability of the broiler chicken production:

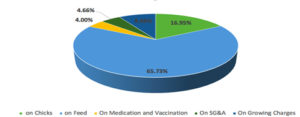

1) Input Cost Drivers: The basic cost driving factor in broiler chicken production are broiler day old chicks, feed, medicines & vaccines, administrative overheads as well as the rearing cost. Out of all the input cost factors, feed and chick cost comprise of close to ~90% of the total broiler production cost. Therefore, fundamentally the Cost of feed production or feed purchase cost and day-old broiler chick production cost or buying price of day old broiler chicks plays a significant role on the total cost of broiler production.

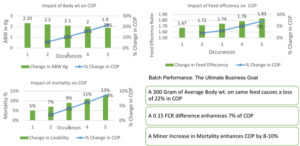

2) Performance Output: The resultant performance of the broiler batch in terms of liveability, FCR, body weight attainment and the yield %age are the outcome related factors which determines the overall cost. The below schematic diagram illustrates the implications of the performance parameters and their efficiencies on the overall performance of the broiler production cycle.

The basic action points that play role in optimizing the cost such as:

- Balanced nutritional formulation: Alternate resources and formulation based on season, raw material price and availability ensuring best feed conversion ratio.

- Health Monitoring: Scientific approach on bio-security and immunization and disease control process to ensure highest liveability with maximum yield.

- Best management practices: Ensuring conducive environment for the broiler birds in the shed leading to highest daily body weight gain.

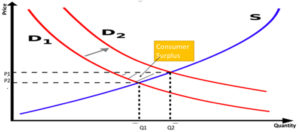

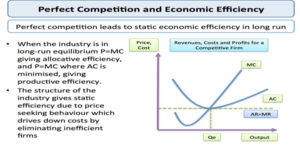

3) Volatility in Broiler Chicken Market Rate: Although the cost optimization is the driving factor in the perfect competition scenario like broiler chicken production wherein every producer in the market produces identical product, but volatility of the market rate is an equally important area to look at in the economics of the broiler production cycle. Many often broiler farmers cannot make profit due to the volatility of the market rate in spite of the fact that their production efficiencies are optimum and cost is under control.

The major concern of the broiler chicken production sector is the information asymmetry on demand and supply leading to the price discrepancies. At present, the Price dynamics is based on a bunch of assumptions more than the basis of the data. Like any other agricultural perishable commodity, Broiler chicken too witnesses a high volatility in pricings.

Dynamics of Marginal Cost and optimum quantity production and its relationship with Law of Diminishing returns:

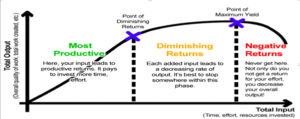

The basic objective of the marginal production Vs Marginal cost analysis is to establish the implication of the change in total cost Vs change in output over a period of time, The theory of marginal cost is more applicable to the farmers or the producer organisations who has a production capacity with multiple locations and placement plan on a weekly basis. The producer companies or farmers many often intend to ignore the production efficiencies and cost drivers from the perspective of marginal cost theory.

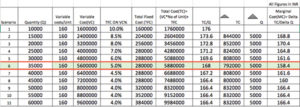

The above self-explanatory illustration indicates the importance of the optimum production quantity in relation to the marginal cost in a controlled variable cost scenario in a given geography. Although in all the above scenarios, the variable cost per unit production remains the same and there has been a projected improvement in total fixed cost, but beyond a certain quantity of production level, the per unit marginal cost starts to enhance causing an economic impact on the production performance ratios.

The three facts based on the marginal cost concept that the broiler producing companies and farmers are to be cautious about are:

- Volume of production in a given geography is considered to be brought into the strategic decision only when the variable cost factors are ascertained to be contained in spite of a consideration of overall reduction in overheads.

- Optimum Volume of production is required to be determined through regular analysis of cost in relation to volume through Change in Cost against change in total output.

- It is advisable to consider rework on production volume as soon as the marginal cost curve matches with the Average Cost, therefore ideally the Optimum Quantity (Qe) = MC/AC =1

Previous article by author: Entrepreneurial Dynamics of FB in Indian Poultry Sector

About the author

Dr. Anjan Goswami, Director in R J Feeds Pvt Ltd, and Navjeevan Hatcheries Pvt Ltd. have got over thirteen years of Enterprise management experience in the Poultry and Food Sector across all the verticals. He has been instrumental in innovating and implementing different types of revenue and investment sharing models which are being adopted by different companies in the sector.Dr. Anjan has mentored and co-founded enterprises in the Health and Service sector. He is the present Gen. Secretary of KPFBA. He brings exposure in the areas of Business Management strategy, financial analysis, investment advisory, due diligence, and corporate restructuring of businesses and has experience of successfully closing overseas M&A deals. The Equity, Debt investments, Joint Ventures, and M&A Agreements have been his area of expertise as well.

Dr. Anjan is a Doctoral Research Fellow at ISB Hyderabad, holds an MBA from the IIM, Bangalore. Apart from being a M.V.Sc, his academic exposure also includes advanced business management training from “Capsim Management Simulation Inc” USA and studies on rural sociology under the program “understanding rural India” from Azim Premji University, Bangalore.