With the current protein ingredient prices increase ( Soya DOC, RSM, GNDOC , CSE , MBM , Poultry meal … etc.) , nutritionist are in a dilemma what to use or what not be used. Also, for summer formulation digestible amino acid levels needs to be increased for performance leading to increase in formulation. This increase in prices have impacted profit realization to a greater extent. In this article, we will try to discuss on the feasible solutions for current challenging situation.

Alternate ingredients consideration in formulation:

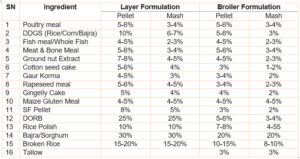

Based on available alternate ingredients and cost feasibility, alternate ingredients can be used to some greater extent. Below is the list of alternate ingredients with maximum inclusion levels which can be used to optimize cost.

Role of QC when formulating with alternate ingredients:

Quality control team plays a very crucial role when alternate ingredients are included in the formulation because the variation in terms of nutrient content (especially Crude protein) and adulteration are more in alternate ingredients when compared to Soya and Maize. With the current soaring prices of ingredients there are complains of lower protein levels in soymeal also. CP levels of Soya DOC claimed to be above 46% is now coming at 44 – 45%. For the feed to be commercially viable among the producer’s stringent QC for ingredient selection is the need of the hour.

Crude protein Levels in feed ingredients of South Asian region with minimum maximum and average values has been put in the graph to follow. Variation can be analyzed and then importance of QC can be made out.

Digestibility of Ingredient and Anti-nutritional effects needs to be considered:

All formulation needs to be formulated on the basis of digestible amino acids. Commercial viability needs to be estimated on the basis of Digestible amino acid levels and not crude protein content of ingredients. Standard Coefficient of Illeal Digestibility (SIDC) is the factor being considered to calculate DAA levels. SIDC values has been developed and published by some companies and research institutes. But these levels have been estimated in temperate conditions in roosters/chicks through metabolic trials. Till we become “Atma Nirvar” for Indian SIDC values, we have no other options but to consider the data developed by the developed world.

When analyzing average digestibility of amino acids in ingredients, Soymeal, MGM, GNE and SF meal falls in highly digestible categories; Fish meal, Poultry meal, Rapeseed meal, DDGS, Cotton seed meal falls in average digestible categories; MBM and DORB falls in low digestible categories.

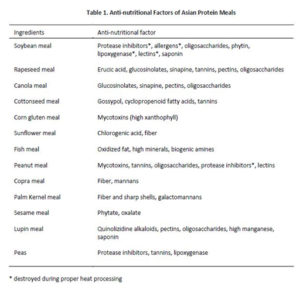

Similarly, there are many anti-nutritional factors present in the alternate ingredients which needs to be considered when these ingredients are included in the formulation beyond certain limit. Non-starch Polysaccharides (NSP) like Arabinoxylans, Beta-glucans, Mannans, Pectin, Cellulose also needs to be neutralized to avoid negative impact on performance.

Use of good enzymes including Protease is a must:

With the use of alternate ingredients, feed enzymes Xylanase, Amylase, Beta-Glucanase, Mannanase, Cellulase, Protease and Phytase have multiple roles to play. Some of the roles are

- Reduces impact of variation in CP and DAA these alternative ingredients have

- Neutralization of some anti-nutritional factors which impacts performance

- Breakdown of insoluble / undigestible substrates to release nutrients

- Reduces gut viscosity and balances microflora useful to gut

- Reduces bacterial/protozoal migration to upper tract

- Prevents leaky gut, optimized nutrient digestion & absorption, profit

Economics and break-even point of enzyme use:

Combination of NSP enzymes, Multi-Protease and Phytase can easily release 100-150 Kcal/kg ME and 5-8% Digestible Amino acid and considerable Ca, Av P, Na depending upon enzyme type and specificity. Multiple trials globally and in Indian conditions have proven it.

With the current raw material prices, reduction in 1-point DLys (Digestible Lysine when formulated based on Ideal Protein) and 20 Kcal/kg ME gives difference of ₹ 300/ton or ₹0.30/kg difference in formulation cost of feed. If this is the cost of enzymes you have been using, then that’s the break-even point. Even if we consider breakeven matrix, the requirement of summer formulation modulation (ME and DAA Increment) can be easily overcome by on top benefit of good enzyme blend.

The other way is to consider matrix for lowering down the feed cost. The more precise and confident we are in terms of raw material quality, finished feed specs the more realistic benefits we can feel with application of enzyme matrix.

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is novellife.bangalore@gmail.com and contact no Landline 080-41326221 Mob- 9611337444)

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is novellife.bangalore@gmail.com and contact no Landline 080-41326221 Mob- 9611337444)