Synopsis: Understanding the role of water activity in maintaining the vital nutrients and protecting it from the microorganisms will be probably the most significant advancement made by poultry feed manufacturers. Water activity (aw) is one of the most critical factors for determining the quality and safety of feed and grain. It quantifies the amount of “free” water available in materials for use by microorganisms and chemical agents.

To face up to the extremely challenging tropical hot and humid weather condition, maintaining overall grain quality over storage requires an in-depth understanding of the sciences involving

- Water activity

- Moisture movement

- Good silo design and silo management program

- Intake grain quality and length of storage.

The first part of the article covered Water activity (aw), reasons for rot, Bio-deterioration, Moisture migration and Corrosion, Grain respiration, Shrinkage, Fungus and Mold and Insect infestation. This concluding article covers Good Silo Design and good Silo management program, Intake grain quality and length of storage.

About the author:

Dr Naveen Kumar, B.V.Sc & A.H (Gold Medalist), M.V.Sc (IVRI, Bareilly) is a food & oil seed grains storage specialist and a finished feed quality expert for Asian and other tropical countries. He also Business Director of Delst Asia and is located in Faridabad, India. He can be reached at naveensharma21@gmail.com

Silo Design

If space is not a constraint, a practical silo size and capacity is to keep the height of silo as short as economically possible as it can greatly ease aeration and the air flow moving to the top. It is more preferably to have multiple silos with smaller capacity rather than lesser tall silo with huge capacity for the ease to facilitate silo management.

Aeration

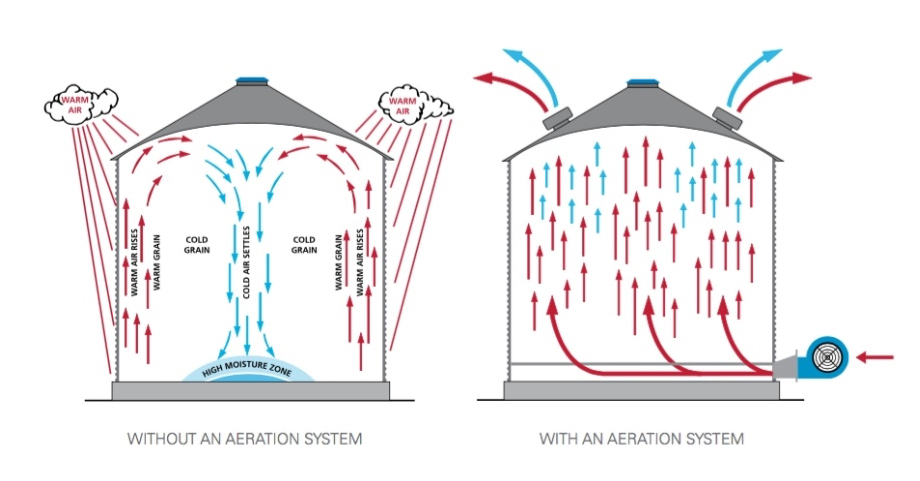

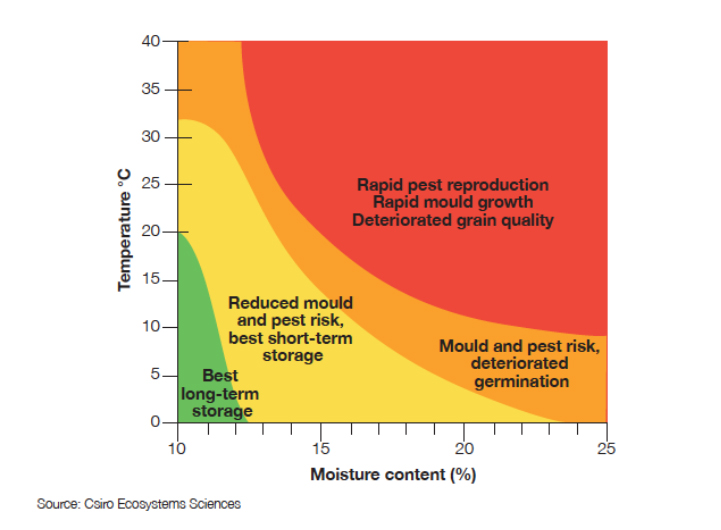

Problem with temperature profile within the grain mass and air current movement can be minimised with effective aeration. Aeration is a tool to manage and control grain temperature, equilibrating with ambient temperature. This is needed to control moisture migration, mold contamination, insect infestation and eventually grain degradation.

In cooler environments, aeration is used to blow in cold ambient air to lower grain mass temperature and to suppress insect development and microflora growth. Whereas in the tropics, a good aeration program with a practical knowledge of working with ambient temperature and humidity will help to minimize heat and to equilibrate grain mass temperature within the silo, reducing issues relating to moisture migration.

As moisture migration moves with the natural air current developing from temperature profile within the grain mass, aeration can help in alleviating the phenomena by harmonising grain mass temperature inside the silo.

However, more often than not, aeration system is always under-designed in terms of capacity for the tropics, rendering it unable to cope with dispersing heat in the grain mass. It is more challenging to maintain grain quality in the tropics as the relative humidity ranges from 70-90% while the ambient temperature ranges from 23- 42°C within a day. After a hot day from the scorching sun, a sufficient amount of air flow is required to dispel the heat. Air to grain ratio at a minimum of 0.30-0.40 m3/min air per ton of corn (0.25 cfm per bu) is required. However, most aeration system that comes with the silos are frequently supplied with much lower capacity around 0.11-0.13 cfm per bu range.

A good aeration program with a sound practical approach of working with ambient temperature and humidity will help to minimize heat and to equilibrate grain mass temperature within the silo, reducing issues relating to moisture migration.

In colder countries, the relative humidity is lower than 65% with very cold and cool temperature in most part of the years. This does not post much problems, except to aerate ambient cold air to cool and equilibrate the overall grain mass temperature to the center of the grain mass. The concern is a small period during the warmer summer, as there is now the issue of managing the temperature and humidity variance between day and night.

Roof ventilation is an important aspect in regulating respirated warm air under the roof space and more nos. of roof vents should be provided for silos in warmer regions. Roof vents should be positioned near the peak of the silo as their function is to remove hot air from headspace. With better efficiency of expelling the warm air coming off the grain, a higher volume of external cooler ambient air can be pulled into the roof space of the eave.

It is strongly recommended to install two units of electric extractor fan per silo for rapid extraction of hot respirated air out to the surrounding.

Good intake management (good filling practices and cleaning to rid dust and foreign material) can assist aerating air flow. Air usually flows along path of least resistance within the silo. Dead space is normally formed due to dust and contamination in grains.

It is advisable to not overfill the silo to the brim but up to the second last ring max, and practice coring after fill. This also assist in better air flow from the roof eve, giving sufficient headspace which also helps in providing a better air cushion between the roof space and the top of grain surface. Hot respirate air has to be continuously extracted out to avoid condensation on the underside of the metal roof at night.

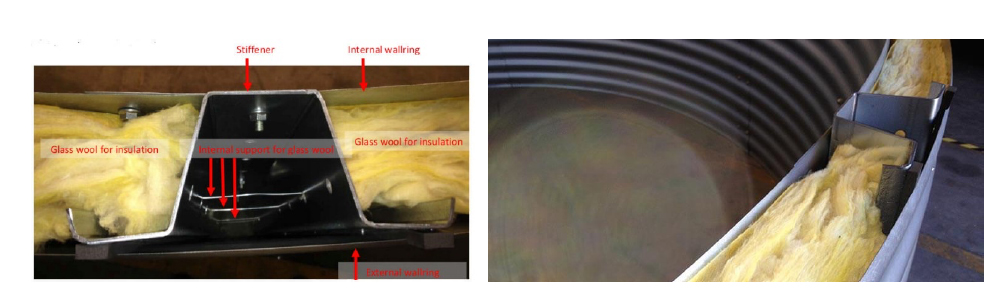

Insulated silo wall is a good option but costly. Insulation prevents temperature differential between day and night, controlling temperature profile to minimize moisture migration. There are three types of insulation which is single sheet, double sheet and a combination of double sheet insulation with insulation material.

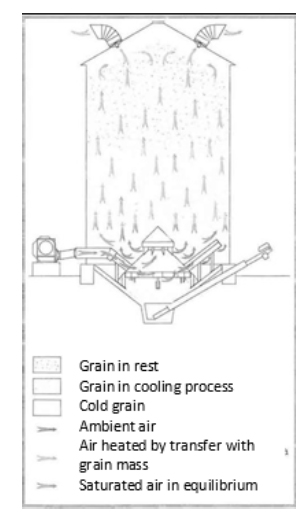

Drying and Silo Operation

Drying helps ensures corn moisture to be kept low and uniform within the maximum safety for grain storage. After the drying process, grains should be transferred into a temporary storage silo or a tempering bin to cool them to ambient temperature. Grains that failed to cool sufficiently after drying may cause a heat steeping effect inside the storage silo, leading to moisture condensation and increasing rate of moisture migration in the grain mass.

https://siloscordoba.com/blog/grain-storage/what-is-a-tempering-silo-and-what-is-it-used-for/

Corn loading

Before loading into the silo, remove dust, fine particles and damaged grains. This eliminates spout lines that decreases the efficiency of aeration. When there are less fines in the grain mass, it is less challenging for storage management as there will be less dead space within the silo, improving air flow distribution and aeration efficiency.

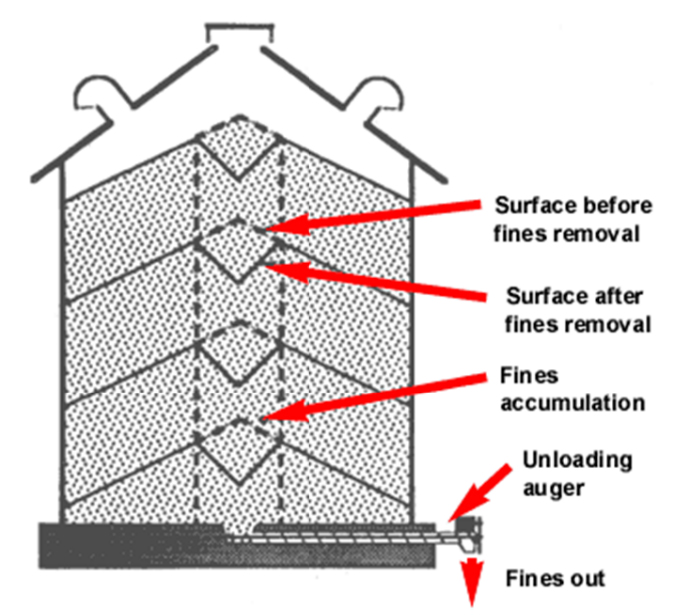

During the loading of grains, there are additional steps for managing fines. Using the center unloading augers to periodically unload some of the grain to remove any remaining fines. This method is often known as coring. When filling, unloading auger is run at least daily or more often to remove the peaked grain, forming an inverted cone with diameter in the range of 5-10 feet. Grains that are removed can be cleaned and mixed with other grain to be putback into the bin.

Mold control begins with moisture control

All the suggested approach (discussed previously) in managing moisture and temperature helps to minimise grain degradation over storage, but moisture migration is still very uncontrollable. This results in corn caking and sweating in the internal wall, leading to mold contamination and grain degradation…Henceforth, the use of mold inhibitors have been a common practice, but always with futile outcome as this is not addressing the root cause of the problem. An effective moisture management program that is able to negate free moisture movement has been proven to contain moisture migration problem in grain storage, hence maintaining the intake quality.

An actual field storage trial on corn storage was conducted, comparing control (with a normal mould inhibitor program) and treatment (with an effective moisture management program). The control was stored for 8 weeks for early feed production use and the treatment corn was stored and stretched to 16 weeks for later feed production use. Both undergoes the same storage program, but the result shows a very significant difference on corn quality at the end of storage. Despite a shorter storage period, the control batch have darkened germ due to mold contamination. As for the treatment corn, the germ still possess a creamy colour, and retaining the original intake quality despite a twice longer storage period.

With a good moisture management program, the silo wall had minimal caking and corrosion with free flowing and healthy grains after long period of storage of 4-8 months. Controlling moisture migration is an effective approach to lock in water activity at a safe level, preventing microbial growth and hence keeping intake grain quality.

Financial loss

The first stage loss is moisture loss due to moisture migration. As moisture migrate, air currents developed from temperature profile. The moisture would accumulate on grain surface and evaporates as weather gets hotter or during silo management program. On average, a minimum of 0.5% of moisture is lost with proper silo management, but if it is not managed properly, moisture loss can go up to 1-1.5%. With the current corn’s price, it will cost approximately US$ 1.50-3.00 per ton of corn stored due to moisture loss.

The second stage loss is when silo management is not properly implemented where ventilation fails to remove free moisture. The three main losses in this stage are the loss of carbon, reduced metabolizable energy and heat damage in grains due to mold contamination.

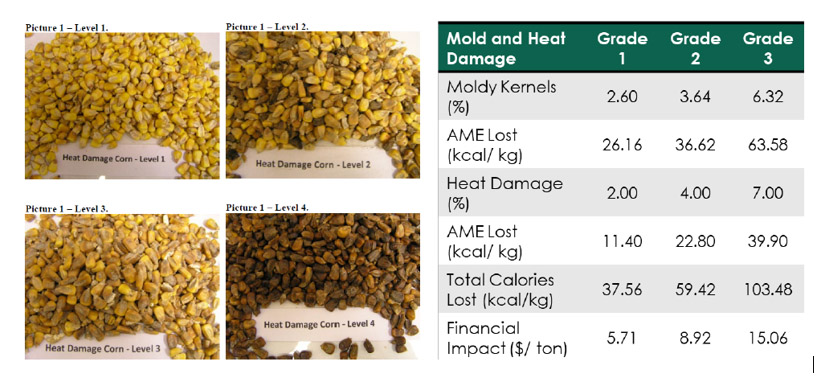

different parameters that are affected by mold and heat damage in corn

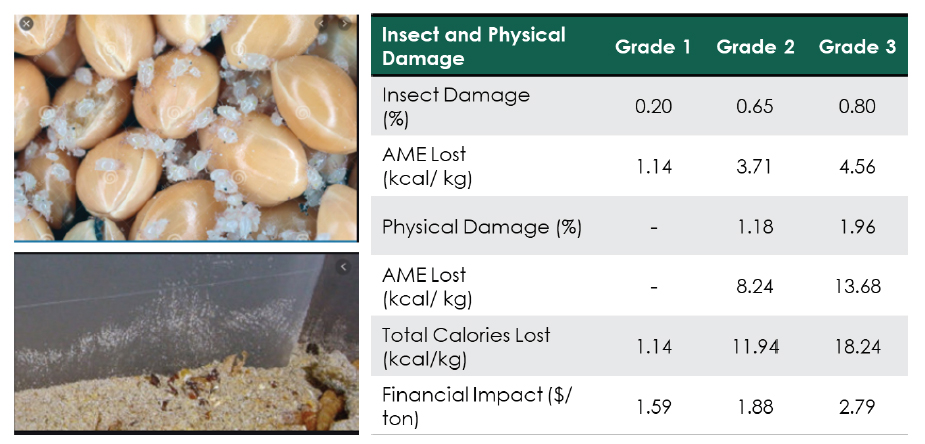

The third stage of loss is when moisture migrate, causing the corn kernels to dry and their surface becomes brittle. When this occurs, there is a risk of corn fragmentation as grains move in the silo. This will increase the chances of insects and mite infestation. Mite and insects cause physical and nutritional damage to the corn and eventually damaging the livestock production as the presence of mites will cause feed rejection and thus feed wastage and the loss of animal performance.

The total amount of loss is alarming. As much as $22.00 per ton of corn is lost in the formulation process. The losses above have yet to include financial impact on farms whereby even minimal mite infestation is able to negatively affect the feed conversion ratio. If losses of nutrients and insect damage are not tackled at source, expensive additives are used to compensate nutrient deficiencies and mask health related problems.

Conclusions

The benchmark to gauge a successful grain storage program is to observe the remaining corn at the bottom of silo after gravity unloading. Ideally, the germ should have a creamy appearance. If the germ area is discoloured even to a slight shade of grey, this is a sign of failed grain storage program. There should also be no visible sign of caking and sweating patches on the side wall. Negligible insect infestation is also a good sign.

The damaging consequence of fungal contamination, loss of nutrients, lost metabolizable energy value of grains greatly impacts feed quality, animal performance and a great economic loss.

All the suggested proper silo engineering set up and silo management practices is to minimize damage if there is a need for long period storage. A proven chemical approach in reducing moisture migration with good aeration management can greatly confine moisture challenge to preserve intake grain quality under the most challenging weather. It is important to control water activity to reduce microorganism activities and degradation of grain. Addressing a pending mold issue with a mold inhibitor treatment is not the answer to keeping grain quality.

The grain and feed industry loses millions of dollars yearly from damaged grain, weight shrink, lost and undigested nutrients, and costs incurred in the attempt to disguise or neutralize problems associated with grain degradation. Much of the repair costs can be cut down if proactive decision is taken to minimise the damage. Proper corn storage management with an effective program will greatly maintain the intake quality and minimise losses.

Featured Silo Image photo created by standret – www.freepik.com

References Afsah H., Leili S., Jinap, S., Hajeb, P., Radu, S. and Shakibazadeh, Sh. (2013). A Review on Mycotoxins in Food and Feed: Malaysia Case Study. Comprehensive Reviews in Food Science and Food Safety. 12. 10.1111/1541-4337.12029. Atanda, S.A., Pessu P. O., Agoda S., Isong I. U., Adekalu O. A., Ehendu M. A. and Falade T. C. (2011). Fungi and mycotoxins in stored foods. African Journal of Microbiology Research. 5(25). 4373-4382. 10.5897/AJMR11.487 D'orazio, M. (2012). Materials prone to mould growth. 10.1016/B978-0-85709-122-2.50012-7. Mathlouthi, M. (2001). Water Content, Water Activity, Water Structure and the Stability of Foodstuffs. Food Control. 12. 409-417. 10.1016/S0956-7135(01)00032-9 Tapia, M.S., Alzamora, S.M. and Chirife, J. (2020). Effects of Water Activity (aw) on Microbial Stability as a Hurdle in Food Preservation. In Water Activity in Foods (eds G.V. Barbosa-Cánovas, A.J. Fontana, S.J. Schmidt and T.P. Labuza). 1002/9781118765982.ch14 Yasothai R. (2019). Storage Losses in Feed Ingredients by Insects and its Control. International Journal of Science, Environment and Technology. 8(1). 44-49.