NECTRA, France has developed an innovative system for Hatcheries where eggs arriving directly from farms get the processing done directly on the eggs trays.

NECTRA, the leading French manufacturer and supplier of Hatchery and Laboratory automation equipment (for Hatchery) has developed an award-winning innovation (at Eurotier 2021) called ‘’SMART’’ for hatching egg REFILLING made directly on tray. The innovation provides an ON TRAY ORDERLY EGG REFILLING SYSTEM // NO ROCK & ROLL ORDERLY REFILLING.

Current Practice:

Currently hatching eggs collected from Farms can only be collected by being rolled over on belt conveying System. The eggs from different source are all rolling on the same conveyor until they get processed, separated by weight, and packed small end down (air chamber up) into setter trays to be incubated.

In very large companies, with large number of farms (often in Asia but not only) it is preferred to process all the eggs in a same processing center within the hatchery where hatching eggs from various farms are brought on egg trays or directly on incubation stackable setter trays to save cost, unloaded onto a conveyor and start rolling to be processed.

Disadvantages of old collection system :

- Eggs get micro crack by hitting each other’s which reduces hatchability and increase contamination

- Since thousands of eggs pass on these conveyors and each of them would roll hundreds time on the belt with extensive rubbing from eggs shell to egg shell and from eggs shell to conveyors, they can and do become extremely contaminated with a high risk of shared contamination.

- If breeders flocks get older or if the shell quality get fragile eggs break more easily and any leak from a broken egg will quickly dirty the belt which in turn will stain the shell of many good eggs.

- Also modern genetic have made the egg so round that it is difficult even with current automated machine that roll eggs to identify the small end from the large end with the egg chamber; Therefore for broiler hatching eggs, the amount of eggs collected upside-down have become quite important with manual collection and even automatic packers for hatching eggs commonly show errors of 2 to 4 % of eggs packed upside-down ….. that goes undetected through the incubation process and affect the hatchability rate.

The Innovation: In Tray “NO ROCK & ROLL ORDERLY REFILLING TECHNOLOGY”

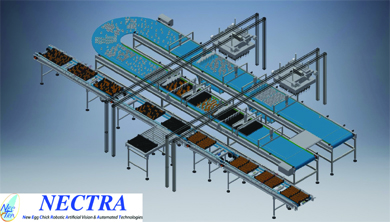

The new SMART refilling technology by NECTRA is part of an innovative system where the eggs arrive directly on incubation trays from the farm and get all the processing stage directly on the eggs tray, weighing the eggs, checking and removing or repositioning upside-down eggs but most important of all being able to refill random empty spot in tray whether the trays are mostly empty or mostly full in a single movement and in a very fast manner and without egg rolling.

This technology allows empty egg position randomly shared within a tray to be filled up automatically at high speed and in one single deposit regardless of how many eggs need to be refilled and regardless of their random repartition. Therefore, egg can be transferred from any type of farm egg trays into any other type of incubation trays in a fast manners regardless of whether the two trays match of not (no common divider factor between egg number of each tray) . it is done fast and in one shot.

It allows completion of incubation trays automatically without manual intervention regardless of the shape variation between farm trays and incubation trays and regardless of the number of eggs to move. It uses several NECTRA Contactless technology to detect the air chamber and remove or reposition the upside-down eggs. Until today handing hatching egg is quite time consuming so the industry was forced to transfer r hatching eggs on belt and let them roll hundreds of times …. therefore, increasing significantly the cracks and cross contamination of breeder hatching eggs and still displaying 2 to 4% upside-down.

With the SMART system, hatching eggs are no longer rolled; They are initially either collected or transferred directly on farm or hatchery setter trays. The SMART refilling technology process them directly on the trays without removing them for quality & crack checking and for individual egg weighing. Upside-down eggs are identified without contact and returned in the right position automatically ( Or manually); During the process eggs may be separated into various weight category directly on setter trays Any empty position in any tray is refilled automatically by the SMART refilling system. The system is composed of 3 parallel conveyors; the first one carries the trays to be refilled either in part of wholly, the second one carries the freely moving cups being filled up with one egg each and the third one carries freely moving empty cups.

The eggs are first transferred on moving cups able to move freely on a belt. At the start and at the end of the belt the cups filled with eggs pile one behind another to generate the exact shape of the tray to be refilled. Eggs on cup cannot hit or touch each other. Empty cups are removed by the ‘’SMART’’ innovative system able to refill eggs into trays or onto cups while at the same time removing cups without eggs on a side conveyor where they will return to get filled up.

The SMART refilling system for the first time provides a safe and sane solution to process hatching eggs at the hatchery and minimizes cracks, bioburden and shell contamination….. and even allows you to identify and save 2 to 4% of your eggs set upside-down in a contactless manner.

Source: NECTRA , France / EUROTIER 2021

time has been reduced to 1 second per hatching egg. In three-shift operation with 20 hours of operation per day, one SELEGGT Circulus sampling unit therefore has a weekly capacity of 360,000 hatching eggs, corresponding to 150,000 to 180,000 laying chicks, a significant increase in performance in comparison with the predecessor system.

time has been reduced to 1 second per hatching egg. In three-shift operation with 20 hours of operation per day, one SELEGGT Circulus sampling unit therefore has a weekly capacity of 360,000 hatching eggs, corresponding to 150,000 to 180,000 laying chicks, a significant increase in performance in comparison with the predecessor system.