Implementation of the hygiene program in a hatchery is not only sufficient to ensure to produce healthy chicks but also is fallow in breeding farm, broiler farm, processing unit, transport. Successful egg incubation and good machinery are two important factors which results in better hatchability and quality of chicks.

Maintenance of all critical parameters at optimum levels using technology helps in avoiding manual errors. HRMSC is both real time remote monitoring and smart controlling device which helps in maintaining the criticals precisely leading to better management and minimal errors which in turn leads to improved hatchability and reduced cull percentage. Overall, this machinery helps in improving productivity in hatcheries.

What is hatchery in poultry farming?

The industry that produces and distributes chicks that are one day old through artificial incubation is referred to as a “hatchery.” In simple words hatchery is where the fertilized eggs are incubated, and chicks are hatched before being sent to a farm to be raised for market. Andhra Pradesh tops the chart of poultry production in India followed by Tamil Nadu, Maharashtra, Telangana, West Bengal, and Karnataka.

What should be the location and site for hatchery in poultry farming?

The poultry farms and hatcheries should be in an area which is far away from industrial and residential areas. It should have good ventilation for air and light and basic requirements of water and electricity. The temperature of the environment for the birds should be 22-30 degree Celsius and the relative humidity should be 30-60 %.

- The distance between the hatchery and the chicken house should be at least 1500 feet (460 metres). The hatchery should be kept far from breeding farms, feed mills, and grain storage facilities, though.

- The hatchery area should be a distinct building with a separate entrance and exit from the chicken farm.

- Size of the hatchery is dependent upon the number of chickens to be hatched in each setting or each week based on the local demand or supply of day-old chicks.

- The rooms need to be set up differently to make greater use of the space available, provide a quicker path for the eggs, and limit employee movement.

- The structure of the hatchery should allow hatching eggs to be taken in at one end and the chick removed at the other.

What are the main parameters of hatchery management?

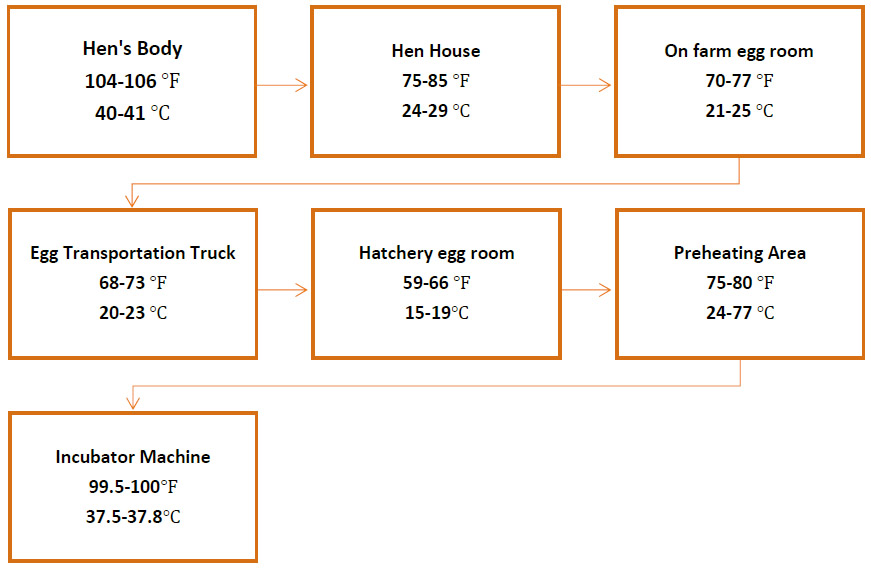

Temperature– According to principles of incubation, incubation temperature should be maintained between 99o and 100o Fahrenheit, but the acceptable range is 97o– 102o Fahrenheit. The optimum temperature for chicken egg in the setter (for first 18 days) ranges from 99.50 to 99.75o F and in the hatcher (last 3 days) is 98.50o F.

Humidity– Recommended incubation relative humidity for the first 18 days ranging between 55 to 60% (in setter) and for the last 3 days ranging between 65 and 75% (in the hatcher). Higher humidity during hatching period is given to avoid dehydration of chicks.

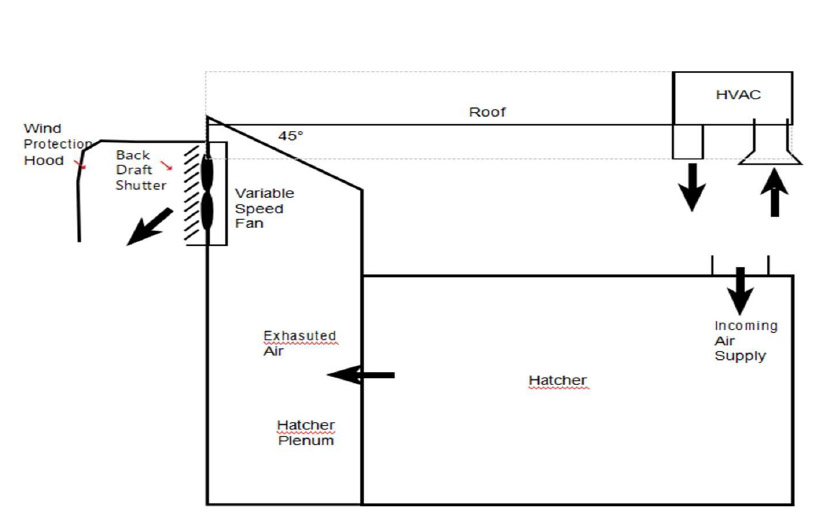

Ventilation (Oxygen and Carbon dioxide level and air velocity)- The setter’s air has an oxygen concentration of about 21%. The hatchability decreases by 5% for every 1% decrease in oxygen. The tolerance level of CO2 for the first 4 days in the setter is 0.3%. CO2 levels above 0.5% in the setter reduce hatchability and completely lethal at 5.0%.

Position of eggs– Holding eggs for artificial incubation should be done with the large ends upwards. Eggs are typically laid large end up during the first 18 days (in the setter) and horizontally for the final 3 days (in the hatcher).

Turning of eggs– Eggs should be turned at least 8 times a day. In large commercial incubators the eggs are turned automatically each hour i.e., 24 times a day. Most eggs are turned to a position of 45o from vertical, and then reversed in the opposite direction to 45o from vertical. Rotation less than 45o are not adequate to achieve high hatchability. Turning is not required in hatcher.

What is Hatchery Management?

Implementation of the hygiene program in a hatchery is not only sufficient to ensure to produce healthy chicks but also is fallow in breeding farm, broiler farm, processing unit, transport. All the person who involves in this process should be aware of all measures, facts, and procedures of hygiene. A collective approach is the only way to ensure best hygienic condition in the hatchery.

The most important goal of any hatchery is to introduce the best quality parent flock with the highest hatchability. Therefore, managing the daily operations of contemporary commercial hatcheries is a crucial managerial task. It’s critical to manage machinery and eggs well.

Three primary factors determine the best quality chicks’ maximum hatchability. They are:

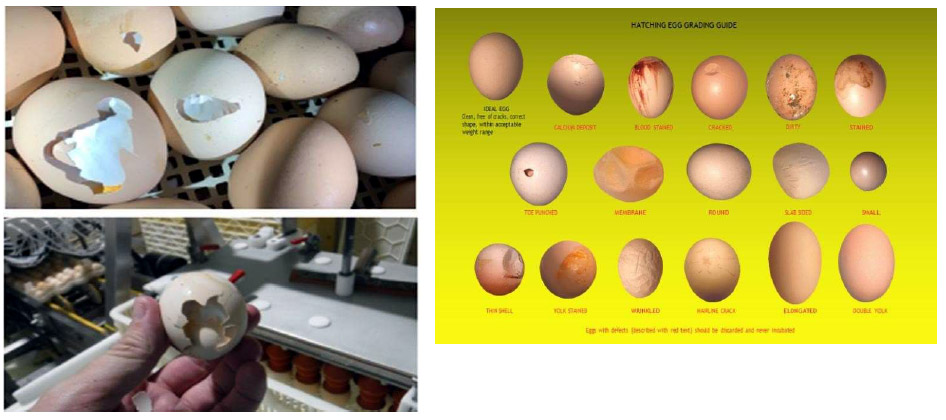

- Good quality healthy eggs.

- Successful egg incubation.

- Efficient egg handling equipment and good operation from egg collection on the supply farm to the distribution of chicks from the hatchery.

What are the problems in hatchery?

Despite a batch’s success, it must constantly be watched over. It is advised to open eggs that are still in the tray for all batches at least once every two weeks. Since the root of lower birth rates isn’t always identified in the hatchery, it can be challenging to identify the cause in some cases. The issue may have started in the feed factory or be related to the health of the breeders, their management, egg storage and transportation, etc. Additionally, elements such as temperature and humidity may contribute to an anomaly.

The problems that are generally faced in a hatchery are as follows:

1. Broken out eggs.

2. Chicks hatch late.

3. Death of chicks.

4. Reduced growth of chicks.

5. Weak chicks.

6. Exposed brain.

7. Crooked toes and spraddled legs.

8. Loss of water from eggs.

9. Short or missing beak.

Why are the hatcheries in poultry industry lagging?

How much ever we try to technologically become strong, we must remember that we are still lagging in the fields of animal husbandry. Till today, we face difficulty in proper management, marketing, transportation, and basic facilities.

Every hatchery strives to generate the greatest number of good quality birds from viable eggs. Analysing the eggs that are still in the trays is one of the most effective methods for achieving this goal. A chick may fail to free itself of the shell for many reasons. They include chick strength, chick position, air cell position, disrupted hatch, and improper incubation humidity.

Have you ever thought what can be the solution to these many problems? It is high time we should start thinking on these factors to prevent anymore losses.

MLIT PoultryMon has the perfect device which can be the solution to all these problems. The Hatchery Remote Monitoring with Smart Controller (HRM-SC) is a supernova solution which provides real time remote monitoring of temperature, humidity in the hatchery along with several other parameters like rack turning, fan rpm/speed, power supply and door condition. The gateway sends cumulative information from about 30 HRM devices to the cloud. The smart controller controls the criticals in the incubator with fully integrated alarm management, alerts automatically and detects changes to temperature, humidity, fan rotation, malfunctioning, door open or power loss in setters and hatchers.

As a result, we can see 1-2% reduction in risk, 1-2 % increase in hatchability, 30-50% reduction in cull percentage, reduction in 3% of electricity consumption, improved quality and quantity of the chicks, better labour management and bird welfare.

For more information, email info@mlitsol.com, website: www.poultrymon.com

Related News: Husband-Wife Duo Create Real-Time Remote Monitoring Solution for …