Dietary Electrolytes consideration while formulating with alternate ingredients

The current situation is demanding use of alternate ingredients to optimize cost. Feed when formulated with alternate ingredients, there are few things which at times becomes critical and effect broiler performance. Variation in quality of alternate ingredient, ANF (anti-nutritional factors) limitation is really of big concern while formulating with these and we have discussed many a times in Poultry nutrition bites. One parameter which is generally overlooked with use of alternate ingredients in formulation is the electrolyte balance of finished feed.

Na, Cl, K and S elements are important:

Sodium (Na), Chloride (Cl), Potassium (K) and Sulphur (S) are the elements involved in the acid base equilibrium in the bird’s body. In addition, they play important roles in the normal metabolic function of the body, for example, Na is required for the absorption of both glucose and most amino acids. Na and Cl are both contained in normal table salt and K occurs widely in plant material. Small amounts of each of these elements are critical for the well-being of all animals. Since they cannot be synthesized by the bird, they are construed to be essential in dietary terms. In large amounts, they have a deleterious effect.

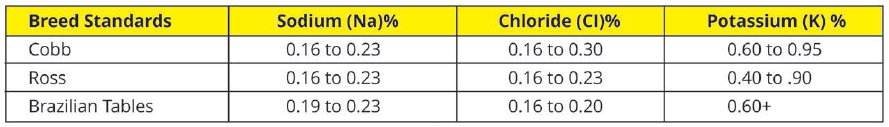

Standards of Na, Cl and K for optimum performance:

The normal salt level used in broiler feed is 0.2-0.5% (2-5kg/ton). This is always an easy item for a practitioner to check on when evaluating a formulation. Bear in mind, however sometimes sodium bicarbonate, sodium carbonate or sodium sulphate are used as a Na source. When birds are deprived of salts, the symptoms are stunted growth, extreme agitation, and cannibalism. If Cl is deficient poor growth and mortalities are seen, with animals showing nervous symptoms, tetany, and excessive hyperirritability to external stimuli. If either Na or K levels are increased, the requirement for the other ion is automatically increased. Some of the standard recommendation of Na, Cl and K levels in finished feed as listed as follow.

Chickens are tolerant of high salt levels in the feed, provided that an adequate amount of drinking water is available. The salt levels in the birds drinking water can be important. If the levels are excessive, then the levels are excessive, then the levels of salt in the feed need to be reduced. Only at levels of greater than 3% of salt in the diet is there growth retardation with reduced feed efficiency. When an excess of salt is fed, birds will show muscular weakness and on post-mortem examination, impaction of the crop and dark colored liver will be observed. In addition, diets high in salt predispose the birds to increased incidences of ascites (water belly) due to increased blood pressure.

Deficiency of K is extremely rare. It is difficult to formulate a ration with a level below 0.4-0.5%. High levels of K cause gastric irritation and wet droppings, a condition that is fairly common in the case of diets containing high levels of soya bean meal.

Chloride levels can be reduced, although most species have requirement of around 1.2-1.5g/kg of diet, below which deficiency symptoms may develop. Care must be taken to meet the minimum Cl requirement when, for example, sodium bicarbonate replaces salt in a diet. Current understanding is that the bicarbonate ion is useful in assisting the bird to overcome the negative effects of heat stress, rather than the fact that it does not contain Cl.

Practical formulating tips:

- Keep Na levels on higher side, this helps in high feed and water intake especially for Indian summers.

- While limiting Cl, the levels shouldn’t go below 0.16%. There is no direct bad effect of excess Cl.

- For optimization use Salt at around 2.5kg/ton and balance the remaining with Soda or other Na salts when formulating with veg ingredients.

- Use of bicarbonates (soda) helps to overcome effects of heat stress.

dEB or CAD or DCAB levels:

Dietary electrolyte balance (dEB), also known as cation-anion difference (CAD) or dietary cation-anion balance (DCAB), is calculated using only the monovalent ions of sodium, potassium, and chlorine. A more comprehensive estimate, however, considers the contribution of divalent ions of calcium, magnesium, sulfur, and phosphorus, but it is used less frequently because it requires more chemical analyses. For all practical purposes, the following equation is sufficient under most commercial conditions:

dEB (mEq/kg) = 1,000 ´[Na(g/kg)/23 + K(g/kg)/39 – Cl(g/kg)/35.5]

In broilers, an electrolyte imbalance can cause tibial dyschondroplasia, which may affect the metabolism of a number of essential amino acids in particular lysine and arginine. In most situations, it seems as through an overall diet balance of 250 mEq/kg is optimal for normal physiological function, although the range of published figure varies from 200-350 mEq/kg.

While it is true that overall electrolyte balance is of major importance, it appears to be most critical when Cl levels are high. Low dietary Cl levels often have little response to the manipulation of electrolyte balance, but when diet Cl is elevated, it seems critical to make the adjustments to the diet cations such that overall balance is maintained. Bear in mind that microbial fermentation can be impacted on by the DCAB in its environment. It may be true that the bird can self-regulate its own DCAB, but it cannot alter the DCAB of the digesta in the intestine. Feed changes, along with changes in the DCAB, may have a negative impact on the gut microflora and gut health.

Practical formulating tips:

- dEB is important for gut health and microbial fermentation.

- Formulating with dEB levels above 200 in summer always helps but the vice-versa may not be always true.

S levels are very critical when formulating with alternate ingredients:

The 1994 NRC lists the toxic level of S as 14g/kg in poultry; however, this is based on data from 1960. Lesson and summers demonstrated that broiler performance was retarded when high levels of dietary S were present in feed. Raw materials such as canola meal and maize DDGS are relatively high in S. If high levels of supplementation of trace minerals (in sulphate form) are added, and crystalline Lysine in form of Lysine sulphate is used instead of Lysine HCl, then the levels for optimum broiler performance might be exceeded.

More recently, researchers showed that feed intake in broilers was significantly reduced when dietary S levels reached 3.6g/kg using copper and zinc sulphate at supplementation levels of 255 and 1363 mg/kg respectively. However, broiler performance was not affected at these levels. Some nutritionist use sodium sulphate as an alternative to sodium bicarbonate. It may be cheaper but its molecular weight of 32.5, S will change the DCAB to some extent. While it may not do any harm, it is difficult to see any real benefit from this practice. Commercial nutritionists are becoming concerned that, as we reduce the protein levels of our diets and possibly use more Lysine sulphate, there is a danger that we may exceed safe upper limits.

Practical formulating tips:

- S levels are critical and needs to be monitored, levels going above 0.3% may affect performance.

- Rapeseed meal, DDGS, Poultry meal, Fish meal and DORB are high in sulphur.

- S coming from Lysine Suphate needs to be considered.

- S coming from Sulphate form of minerals also needs to be considered.

- Formulating low protein diet with alternate ingredients at times aggravates the issue due to high S levels in finished feed.

For references, questions and feedback write to Novel Life Consultants, Bangalore (India). Email id is novellife.bangalore@gmail.com and contact no Landline +91- 80-41326221 Mob- +91 9611337444)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

References: - Bobeck, E., Payne, R.L., Kerr, B.J. and Persia, M.E. 2013. Supplemental lysine sulfate does not negatively affect the performance of broiler chicks fed dietary sulphur from multiple dietary and water source. JAPR, 22:461-461 Borges, S.A., De Oliveira, J., Fischer da Silva, A.V. and Dos Santos, T.T.2011. Use of electrolytes for birds-the practice of theory. In Proceedings of 22nd APSS Lesson, S. and Summers, J.D. 2005. Commercial Poultry Nutrition, 3rd Ed. Guelph Ontario, Canada: University Books. Nutrient Requirements of Poultry: Ninth Revised Edition, 1994 Rick Kleyn and Peter Chrystal 2020. Broiler Nutrition Masterclass, First Ed. British Library, England: Context Publisher 2020

Similar article: Feasible Solutions To Cater High Ingredient Price

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is

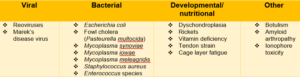

We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

We come across many poultry farmers changing feed suppliers/ integrators once they face the challenge of lameness. Culls as called in local language should be limited to maximum 1% during entire rearing of broilers. In this issue of Poultry Nutrition Bites, we will try to address lameness/culls in broilers and how can it be addressed.

necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

necropsied. Starting at the feet, note the condition of the footpads, any joint swelling (pus or serous fluid), the thickness and firmness of the gastrocnemius tendon, and any erosions in the hips. Slice the top of the hock from the medial side to inspect cartilage formation for dyschondroplasia. Bend the tibia to detect reduced bone strength, which will be affected in rickets. Open the abdomen and check for lesions, especially around the air sacs. Check the keel for breast blisters. Check the sciatic nerve if lameness caused by Marek’s disease is suspected. With a sharp surgical blade slice ventrally through the spinal column to look for abscesses, which can be found on the free thoracic vertebrae. Check other joints, such as those of the wing, for swelling or abnormal fluid. Note the findings in each bird to determine the predominant cause. If a bacterial etiology is suspected, swab the affected joints and place the swabs in bacterial transport medium. Collect blood samples from 10 birds for serology. Collect feed and water samples. If feed retention samples are kept by the farm, collect samples from the time when leg problems were first noted.

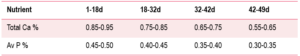

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption.

Excess Ca in diets depress feed intake, growth rate. Trials across the world have proven that. Indian farming is full of stress and infections. Including acidifiers in feed is a common practice in India to lower pH. Increasing Ca levels in feed increases pH of crop and digesta in the small intestine. The beneficial effect of acidifier is minimized by this. To increase feed density nutritionist generally increase oil levels in summer. Excess Ca levels in diets form soap with oil/fats and lowers its digestion and absorption.

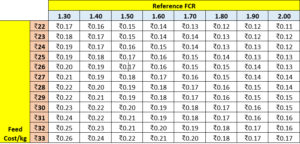

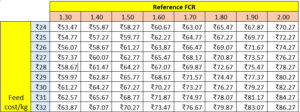

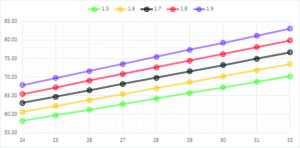

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost)

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost)