Broiler performance is graded in India by comparing Average body weight, Average day gain, FCR, CFCRs, Livability and EEF/PPI (European Efficiency Factor or Poultry Performance Index). 9 out of 10 Poultry Production companies in India work on performance optimization. They formulate very high-density feed so that they can grow birds to be marketed early say at 32 to 35 days with very low FCRs (some getting even below 1.4). They celebrate these achievements and proudly share this performance in forum and medias.

There are also some poultry producers who work on Profit optimization. Their performance is average to low, but they make good profits silently. They don’t pat their backs for good performance and achievement but are growing month on month in their business.

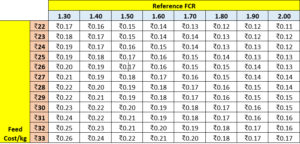

Impact of 1-point FCR difference:

Let’s start by calculating what is the impact of 1-point FCR. The cost of 1-point FCR depends upon the cost at which feed has been made and reference FCR. For e.g., the same 1-point FCR cost will be higher for feed calculated at ₹30/kg than at ₹29/kg. Similarly cost of 1-point FCR will be higher when reference FCR is 1.5 than it is 1.6 or above.

Equations used to calculate are:

Current FCR * Feed cost per kg = Feed cost per live kg

Feed cost per live kg/Projected FCR = Future feed Value

Future feed value – Original feed cost = Cost of 1-Point FCR in ₹

(Figure 1 – Cost of 1-Point FCR in different field perspectives)

In the above table, cost impact of 1-Point FCR at different feed cost and standard reference FCR is mentioned in ₹. From the table is can be made out that if feed cost is ₹30/kg and someone getting 1.60 FCR for his farm cost of 1-Point FCR is ₹0.19 or 19 paisa in terms of Feed costing.(Figure 1 – Cost of 1-Point FCR in different field perspectives)

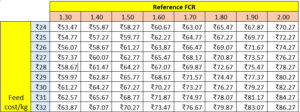

Production cost and margin impact:

Similar mathematical modeling can be applied for calculation of production cost as well as profit optimization also. Assuming current chicks’ price ₹45/unit (its high but this is the prevailing rate), management cost ₹4/bird and standard liquidation/selling weight 2.2kg/bird production cost has been calculated at various feed rates.

(Figure 2 – Broiler Production cost/kg in different field perspectives)

One thing which can be clearly made out from the table is, for profit optimization only better (lower) FCR is not important but also formulation cost. For someone formulating very high-density feed at ₹32/kg and getting 1.50 FCR will have production cost of ₹70.27 whereas moderate density feed formulated at ₹28/kg and getting FCR 1.70 will have production cost of ₹69.87 and will run with more profits.

Some field veterinarians may disagree to this calculation as they have observed more mortality and field challenges with birds growing slowly. They complain of issues related to gut health, respiratory tract after 20 days and feel good when birds are liquidated at 33-35 days. But with good gut health and respiratory infection prevention plan in place, disease challenges can be easily managed. Also, production is a big stress in birds, slow growing birds are less prone to immunosuppression and metabolic disorders. Lower Average Day Gain doesn’t always mean higher mortality which can also be corelated to broiler grown on welfare norms and free range in western world.

Interpretation and commercial use:

- Better performance may not always be better profits, the correct approach must be followed for profit optimization.

- Integrators with limited farming and very stringent farm selection can go with performance optimization approach.

- Integrators with operations across multiple states and looking for expansions should always work on the profit optimization model. The density of feed should be medium to low so that the impact of 1-Point FCR is also less.

- In pockets with very high density of poultry population, the performance of same feed across farms depending upon management is 20-30 Points FCR. For these areas profit optimization concept works the best.

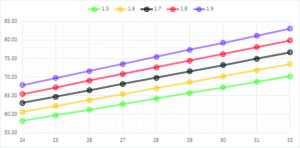

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost)

(Figure 3 –Line graph demonstrating FCR, PC and Feed Cost) - Additives pertaining to gut health, disease needs not to be compromised while formulating feeds at a lower cost. Good health monitoring and management practices are always helpful in keeping diseases at bay.

- Lower to medium density feed can be formulated at a lower cost but the things to keep in mind is the percentage inclusion of alternate ingredients. Minimizing the variation in raw ingredients through good quality control process and use of suitable enzymes are giving edge to the poultry producers following this approach in India.

- Top 2 out of 3 Indian Integrators are successfully following profit optimization approach and they are satisfied with average performance.

For references, questions and feedback write to Novel Life Consultants, Bangalore. Email id is novellife.bangalore@gmail.com and contact no Landline 080-41326221 Mob- 9611337444)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)

(This article is a work of Novel Life Consultant and is for public information purpose only. This has been written to share knowledge on poultry nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company. The views expressed by the writer are their own and their appearance does not imply an endorsement of them or any entity they represent.)