Food safety is one of the main buzz in the present time. As of now food safety was limited to only human and pet food with little concern of livestock feed. But with time now consumers are not only becoming more aware of the quality aspects of livestock rearing but also on the quality of inputs being fed to reared poultry & cattle. One important aspect of prepared feed quality is the stability of the final product.

Changes in physical, chemical or microbiological properties of feed can be considered loss of stability. Water activity (Aw) is one of several important parameters that affect stability of livestock feed. Water activity is a measure of the free moisture in a foodstuff. It is also defined as the quotient of the water vapor pressure of the substance divided by the vapor pressure of pure water at the same temperature.

Changes in physical, chemical or microbiological properties of feed can be considered loss of stability. Water activity (Aw) is one of several important parameters that affect stability of livestock feed. Water activity is a measure of the free moisture in a foodstuff. It is also defined as the quotient of the water vapor pressure of the substance divided by the vapor pressure of pure water at the same temperature.

The water activity scale extends from 0 (bone dry) to 1.0 (pure water) but most foods have a water activity level in the range of 0.2 for very dry foods to 0.99 for moist fresh foods.

Water activity need not to be confused with moisture content. Moisture content is the combination of free and bound moisture. Free moisture can be explained as water that is available to participate in physical, chemical and biological reactions.

Water activity plays a vital role in the microbial stability of ingredients and final livestock feeds. Bacteria, molds and yeast require water for growth; and every microorganism has a minimum water activity below, which it will not grow.

In the previous part, we discussed the Water Activity stability in terms of degradative reactions rates and microbial growth limits as a function of water activity along with different scenario of damages due to uncontrolled water activity. This is the concluding part of the article.

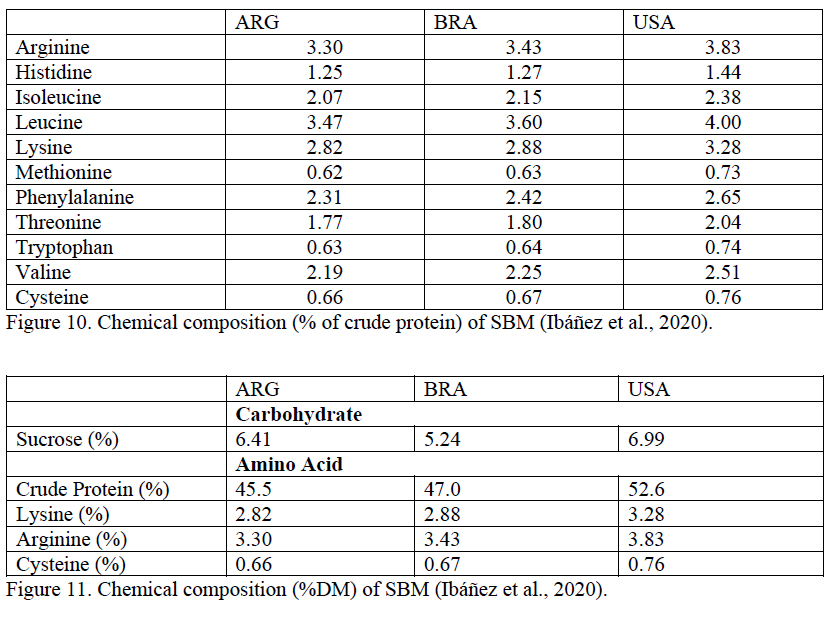

Storage of soymeal in bulk warehouse

Water activity may affect physical properties such as moisture migration, texture and etcetera.

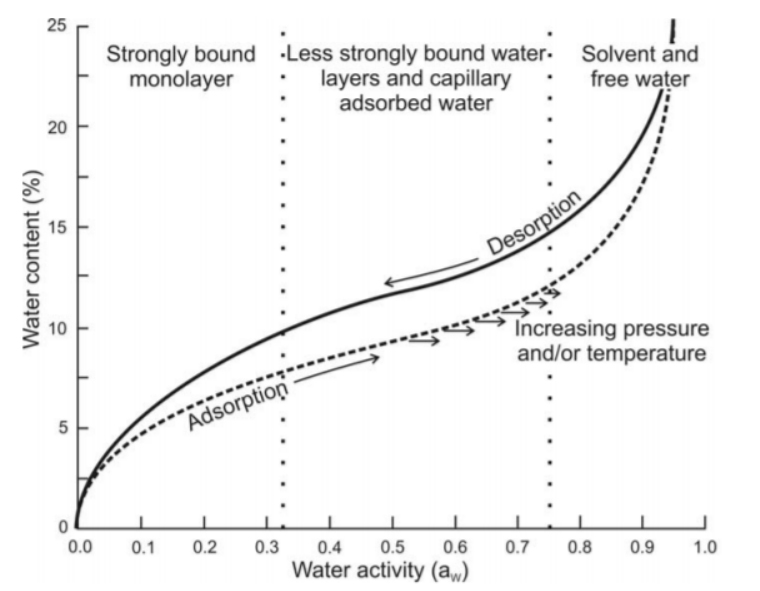

Moisture migration occurs when there is a aw difference between components or with the surrounding environment as the system comes to an equilibrium. Undesirable textural changes can result from moisture migration in multicomponent product. Water migrates from region with high aw to region with low aw until an equilibrium of aw is achieved but the rate of migration depends on structure or diffusion process (o’Connor et al., 2017). Effect of moisture migration with humidity on aw can be illustrated in moisture sorption isotherm as shown in Figure 7. Figure 7 shows how aw changes as water is adsorbed into and desorbed from a product at equilibrium relative humidity and constant temperature. In practice, this moisture sorption isotherm maybe impractical to use as it is complex and unique for each product. Besides, the relationship between moisture content and water activity changes when temperature varies and also when there are any variations in material composition with a modifying effect.

adsorption and desorption isotherms (Airaksinen, 2005).

Water activity affects the biochemical reactions and physical properties of the product.

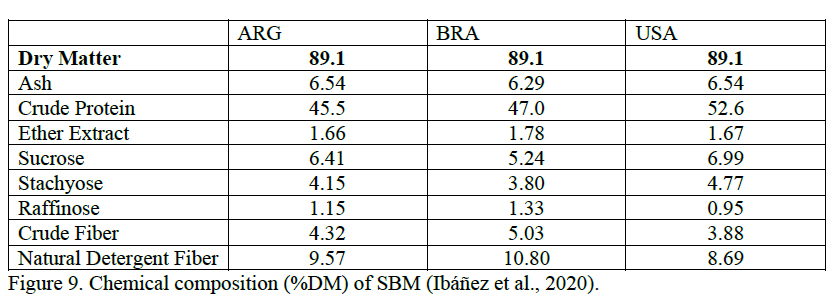

Uncontrolled aw in soybean meal (SBM) storage can cause non-enzymatic browning reaction during processing and moisture migration in the storage. Due to moisture migration, it leads to caking of SBM in storage. Besides, water activity has the ability to influence both the rate and color of non-enzymatic browning reaction, which is also known as Maillard reaction. Maillard reaction (MR) is a biochemical reaction between reducing sugars and amino acids to form Maillard reaction products (MRP) and further progress to Advanced glycation end products (AGEs). MR takes place even at room temperature but at a slower rate. The rate of reaction increases when time and temperature increases, and at a humidity of 40-70%. MR is mostly responsible for the deterioration in protein quality, especially lysine is the most susceptible amino acid (Tanaka at al., 1977). SBM is very vulnerable to MR over storage in a hot and humid tropical condition. SBM has high percentage of lysine, arginine, cysteine and tryptophan which easily react with reducing sugars, resulting in MR and the degradation of amino acids (Ibáñez et al., 2020). Since SBM is widely used as a feed ingredient in feed formula, MR is an unavoidable issue in moist heat feed pelleting process. There are inconsistencies in performance of birds fed with mash and pelleted feed which is highly due to the quality of SBM (Araba and Dale, 1990). A good indicator to determine the degree of MR is the colour change in product. Generally, as water activity approaches 0.70, the rate of Maillard reaction increases. When aw is higher than 0.70, Maillard reaction slows down because the reactants are diluted by too much free water.

Shipment of corn gluten meal in containers

A trial was done to monitor the effects of moisture migration and aw in corn gluten meal (CGM) during shipment from USA to the Pacific Rims.

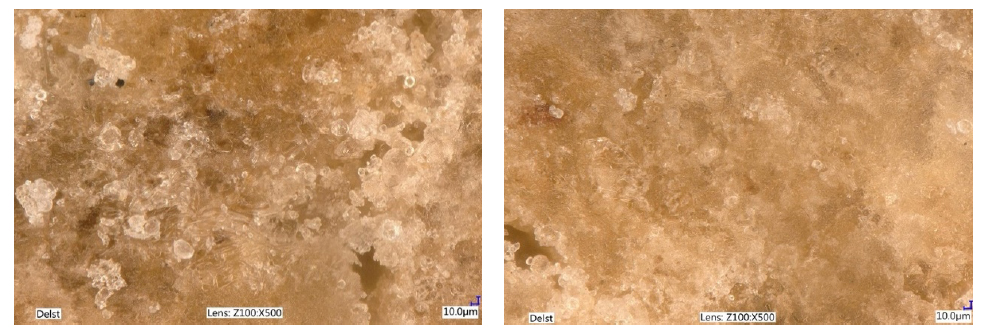

Moisture movement creates stickyness, caking, and mobility issue on mealy material as Figure 12 (Left). However, when aw is controlled, the corn gluten meal has a very different free-flowing characteristic as observed in Figure 12 (Right).

What is worst is that aw has increased substantially with free moisture movement, and the material gets moldy upon reaching port. See Figure 13 (Left). The treated CGM prevents free moisture movement, and aw is hence controlled at a safe level maintaining freshness and the original quality at point of loading, shown in Figure 13 (Right)

Quality integrity of palm kernel pellets

This trial was done to investigate the complain of staleness of products from Malaysia shipped in container to Japan and Korea. 2 MT of fresh products from the same production batch was used with 1 MT Control PKE pellets was bagged and another treated 1 MT PKE pellets bagged. All the bags are stacked on pellets and stored at the hottest areas in production for 90 days to simulate a challenge.

After 90 days, the result was astonishing. Figure 13 shows clearly the difference between control and treatment. The control group (Figure 14 Left) look discoloured, with a stale appearance, and without the aroma of PKE. The treatment group (Figure 14 Right) has a very fresh appearance, maintaining its original quality, and still has a strong PKE smell.

This is another classic case of moisture movement and activated aw compromising the chemical stability of the product. Nutrients and lipids are degraded which explains the poor quality of the control group.

the treated PKE.

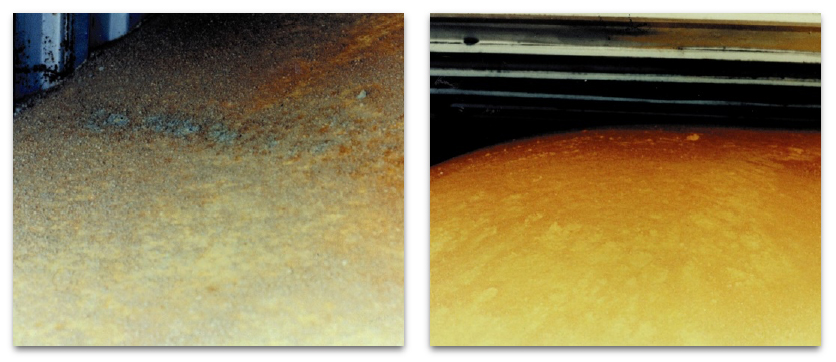

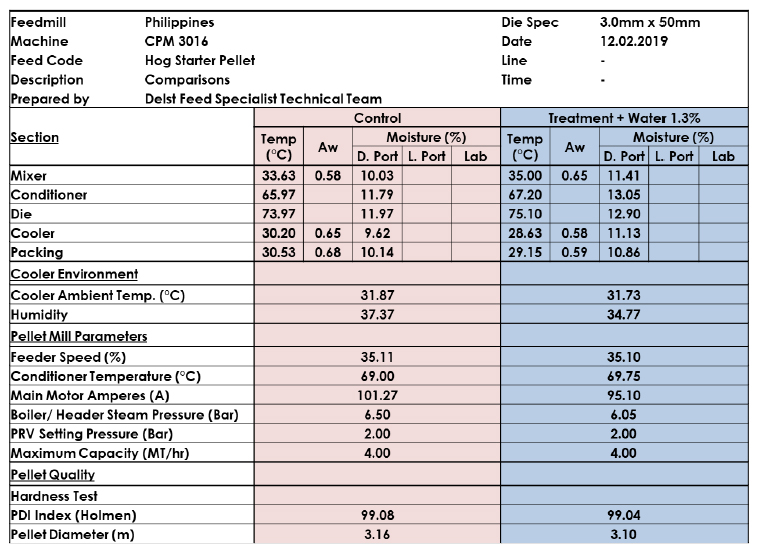

Water activity and moisture content in processed poultry pellet feed

A feed trial was conducted to investigate the addition and capturing of water on the processed pellet feed quality, for starch cooking/gelatinization, data shown in Figure 15. To show the effect of working on a program to capturing water, as in getting moisture from water added at the mixer plus microscopic moisture from steam into the feed chemistry. A process addressed as “positive mash hydration” (This is for the sole purpose of starch granule swelling and sufficient degree of protein denaturation). The result in starch gelatinization is later captured by feed imaging, indicating a loss of birefringence.

With the treatment feed, notice the spike on aw after water has been added at the mixer. Interestingly, the finished feed of the treatment group has a higher moisture content, but water activity is lower compared to the control group. The capturing of moisture for the purpose of starch gelatinization which in turn lock up the hydrolyzed water used in the process of starch swelling/cooking indicates the positive chemistry changes of feed processing.

Picture on the Right is the treatment group with aw of 0.59 and moisture content of 10.86%.

Conclusion

Water activity is a critical parameter in controlling the quality of feed and feed ingredient as it is a reliable indicator and predictor of chemical reactions and microbial responses in the industry. This is how we need to manage and control aw with proper grain storage, shipment of feedstuff, feed processing on both pellets and extruded feed, and handling of mash feed. This will dictate how well we face up to the challenges in keeping the quality of grain over storage, and the processed feed in post-production. A proven approach to managing and controlling aw has been established with proven results. Chasing down a moldy problem with mold inhibitors is like attempting to save a building on fire with extinguishers. The building still gets burnt and ravaged.

References: Ahn, J. Y., Kil, D. Y., Kong, C. and Kim, B. G. (2014). Comparison of Oven-drying Methods for Determination of Moisture Content in Feed Ingredients. Asian-Australasian journal of animal sciences. 27(11). 1615–1622. 10.5713/ajas.2014.14305 Airaksinen, Sari. (2005). Role of Excipients in Moisture Sorption and Physical Stability of Solid Pharmaceutical Formulations. Araba, M. and Dale, N. (1990). Evaluation of Protein Solubility as an Indicator of Overprocessing Soybean Meal. Poultry Science. 69. 76-83. 10.3382/ps.0690076. Gadient, M. (1986). Effect of Pelleting on Nutritional Quality of Feed. Proceedings of 1986 Maryland Nutrition Conference for Feed Manufacturers (USA). 73-79 Jung, H. B., Lee, Y. J. and Yoon, W. (2018). Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes. 6. 69. 10.3390/pr6060069 Labuza, T.P., McNally, L., Gallagher, D., Hawkes, J. and Hurtado, F. (1972). Stability of Intermediate Moisture Foods. 1. Lipid Oxidation. Journal of Food Science. 37. 154-159. 10.1111/j.1365-2621.1972.tb03408.x Leeson, S. (2015). Vitamin Deficiencies in Poultry. MSD Manual Veterinary Manual. Mathlouthi, M. (2001). Water Content, Water Activity, Water Structure and the Stability of Foodstuffs. Food Control. 12. 409-417. 10.1016/S0956-7135(01)00032-9 Ibáñez M.A., de Blas, C., Cámara, L., Mateos, G.G. (2020). Chemical Composition, Protein Quality and Nutritive Value of Commercial Soybean Meals Produced from Beans from Different Countries: A Meta-analytical Study. Animal Feed Science and Technology. 267, 114531 o'Connor, L., Favreau-Farhadi, N. and Barrett, A. (2017). Use of edible barriers in intermediate moisture food systems to inhibit moisture migration. Journal of Food Processing and Preservation. 42. e13512. 10.1111/jfpp.13512. Reid, D.S. (2007). Water Activity: Fundamentals and Relationships. In Water Activity in Foods (eds G.V. Barbosa-Cánovas, A.J. Fontana, S.J. Schmidt and T.P. Labuza). 10.1002/9780470376454.ch2 Tanaka M., Kimiagar M., Lee TC., Chichester C.O. (1977). Effect of Maillard Browning Reaction on Nutritional Quality of Protein. In: Friedman M. (eds) Protein Crosslinking. Advances in Experimental Medicine and Biology. 86. Springer, Boston, MA. 10.1007/978-1-4757-9113-6_22 Tapia, M.S., Alzamora, S.M. and Chirife, J. (2020). Effects of Water Activity (a w ) on Microbial Stability as a Hurdle in Food Preservation. In Water Activity in Foods (eds G.V. Barbosa-Cánovas, A.J. Fontana, S.J. Schmidt and T.P. Labuza). 1002/9781118765982.ch14 Zambrano, M., Dutta, B., Mercer, D., Maclean, H. and Touchie, M. (2019). Assessment of Moisture Content Measurement Methods of Dried Food Products in Small-scale Operations in Developing Countries: A Review. Trends in Food Science & Technology. 88. 10.1016/j.tifs.2019.04.006