TREATMENTS / VACCINATIONS & DRINKING WATER DISINFECTION continue to develop as farms modernize and comply with best practices.

A. Medication & Vaccination through Drinking Water (AL Animal health Line)

A. Medication & Vaccination through Drinking Water (AL Animal health Line)

Among the treatments that can be administered via drinking water are :

- curative / metaphylactic antibiotics, wormers, painkillers, anti-inflammatory (respect vet prescriptions),

- vaccines,

- vitamins, trace elements,

- electrolytes (rehydration),

- probiotics, prebiotics,

- organic acids,

- essential oils,

- bacteriophages, etc.

Advantages of treating via drinking water:

- Sick animals have a tendency for to eat less than they drink in order to compensate for dehydration, body temperature or stress.

- Flexibility required for curative treatments (medicine doses & type + administration periods can be easily adjusted under veterinary control)

- Easy & fast to implement when a problem is detected compared with the delays for production & delivery of medicine premixes.

- The drinking water administration generally leads to significant antibiotic use reduction compared to the feed medication (in a growing number of countries the preventive medication usually administered via feed as nearly disappeared or is now prohibited such as in Europe since 2022)

- Less risk of antibiotic cross-contamination with feed from the feed production unit to the farm.

- Mass vaccination via water is also currently used within more or less 2 hours (time saving)

Please note that when administering medicines/vaccines via drinking water a number of rules should be observed (refer to Dosatron good practices training programs & tools for vaccination, medication, etc..)

How to choose the dosing pump for Medication / Vaccination:

Most of the hereunder criteria to respect are already listed in:

-

The European Medicine Agency 2020 recommendations – Article 106 (6) of Regulation (EU) 2019/6

- The German Din Standard 10529-2

1. Check the minimum & maximum water flow of the dosing pump

-

-

low flow capability (5 or 10 l/h minimum) is a key factor as 70% of treatments & vaccinations are administered to young animals the very first days

-

high water flow capability is important for big numbers of animals & peak consumption periods

-

2. Check the minimum working water pressure & if the dosing precision is affected by pressure :

-

- very important when using header tanks as a water source with low pressure.

- some dosing technologies are injecting the treatment against the water pressure in the pipe (counter pressure). If the water pressure drops which often happen, these dosing technologies could over dose.

3. Select a maximum dosage (injection rate in %) high enough up to 4% or 5% :

-

-

to ensure a good solubility of oral powders (N°1 error in water medication) : most oral antibiotics belonging to tetracyclines, penicillins, sulfamides families & many powder supplements often requires a 4% or 5% dosing capability to insure the solubility into the stock solution of the dosing pump (more water in the stock solution tank)

-

a good solubility in the tank means no pump or drinkers clogging & no concentration variation from the tank to the drinkers > the only way to be sure that all animals have a permanent access to the right dose of medicine (knowing that animals only drink for a few minutes a day, at random)

-

water pipe sanitation after depopulation requires sometime disinfectants/ biocides dosed at 3% to have a real bactericide/ virucide effect & to remove the biofilms

-

high dosing % means a stock solution more diluted with less medicine residues or expensive doses of vaccine wasted at the end of the tank

-

4. Select a dosing pump with a long lifespan + an easy & cost effective maintenance

-

- change seals / wearing parts when recommended

- don’t forget to rinse the dosing pump and the drinking system injecting water after every treatment

5. Select a dosing pump with sufficient in-line dosing and mixing capacity (water + treatment)

-

- to avoid significant variations in treatment/vaccine dose at drinking troughs (given that animals only drink for a few minutes a day, with a highly variable time spent at the drinker at each visit).

To answer frequent water Medication/Vaccination extreme situations Dosatron SAS has launched the DIA4 AL Diaphragm dosing technology (AL: Animal health Line)

Ability to operate at the lowest water flows

Ability to operate at the lowest water flows

(ideal to treat animals from the very first days & small groups)- The only pump compatible with heavy load of minerals into water (iron, manganese, hard water)

- The longest pump motor lifespan thanks to the motor diaphragm

(no motor piston or water meter wearing / best return on investment per m3 of treated water) - The least expensive motor maintenance

(2 motor mechanism part to replace only) - A high dosage capability up to 4%

(to ensure the solubility of most oral powders) - External injection of the additive to protect the motor

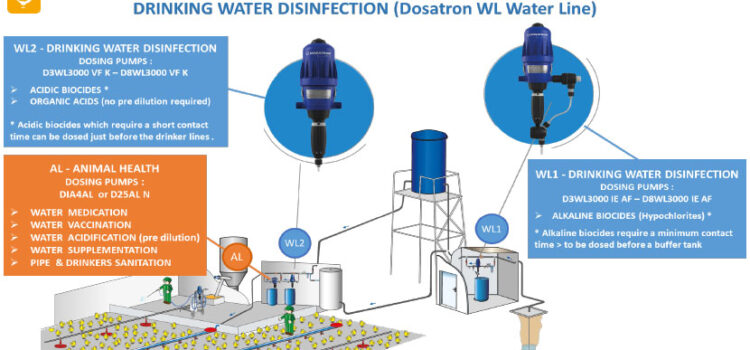

B. Disinfection of Drinking Water (WL Water Line):

Among the biocides that can be administered via drinking water are :

- Alkaline biocides requiring a minimum contact time (dosage before a buffer tank)

• Sodium Hypochlorite – NaClO

• Calcium Hypochlorite – Ca(ClO)₂ - Acidic biocides with short contact time (dosage possible before the drinkers)

• Hydrogen Peroxide – H202

• Chlorine Dioxide – Cl02 (up to 2000 ppm max into the stock solution)

• Sodium Troclosene tablets – NaDCC

• Peracetic Acid – CH3COOOH

In general,

-

Acidic biocides with a short contact time can also be dosed just before the drinking system (just before the Medication/Vaccination dosing pump)

-

Alkaline biocides such as traditional hypochlorite (bleach) with a longer contact time should be administered before the water tank to ensure a minimum contact time.

Note :

-

Always analyze your water quality (bacteriological & physico-chemical analysis) twice a year & regularly check the residual biocide level at the end of the drinking line.

-

Warning regarding vaccinations : Don’t forget to stop water disinfection before any vaccination via drinking water (use the existing inhibitors such as Sodium thiosulfate for chlorine or sodium bisulfite for hydrogen peroxide with blue die / Never use skim milk powder with dosing pumps)

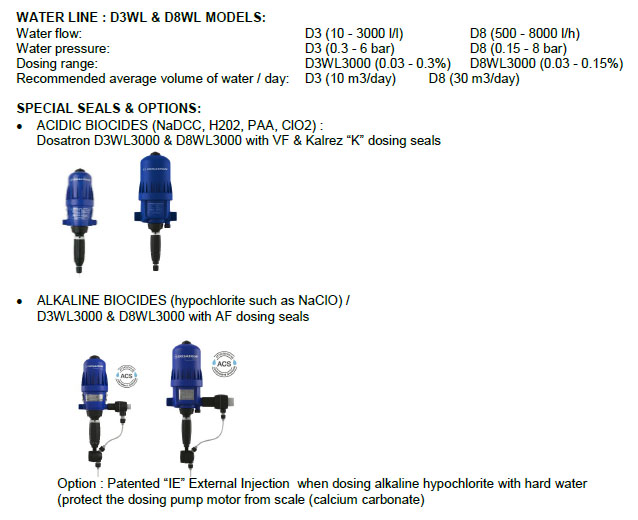

To answer the Water Disinfection needs Dosatron SAS has launched the new dosing pumps D3WL3000 or D8WL3000 (WL: Water Line)

Very low dosing capability with a minimum dosage at 0.03%

Very low dosing capability with a minimum dosage at 0.03%

(to be able to prepare a lower volume stock solution of biocide for 1 to 3 weeks water disinfection 24/7)- Longer motor lifespan

(Cost effective > no need to change the complete motor when worn > just replace piston rings & 1 spring) - Easy onsite maintenance with no tool

(please refer to Dosatron maintenance videos) - Low number of motor parts with high chemical resistance materials

(no metal part corrosion) - Self-priming + no need of an Off-gassing head option on the dosing pump for biocides such as Hydrogen peroxide

(oxygen gas release leads to problems with other technologies) - No electricity shortage or surge risk

(Dosatron is a hydraulic / mechanical dosing technology with an easy onsite maintenance)

For details, email at kaushik.shetty@dosatron.com or visit https://www.dosatron.com/en-us